KOENIG RESTRICTOR® SERIES RE – OVERVIEW

The KOENIG RESTRICTOR® Series RE is designed to restrict flow in fluid systems and is available in a variety of orifice sizes. These flow restrictors are tamper resistant and provide proven performance even in high-vibration applications, with a maximum working pressure of 210 bar (3045 psi) depending on the base material and part size. Series RE restrictors securely install into drilled holes with fast and easy installation, effectively controlling the flow of both fluids and gasses.

With complete design-in engineering support, and global expertise in a variety of sealing and flow control applications, SFC KOENIG is ready to assist with your orifice flow restrictor needs. To assist with part selection, we have developed a Flow Rate Calculator and an Orifice Size Calculator that can help identify which Series RE orifice restrictor fits your application requirements, or use our Product Selector to identify the best KOENIG RESTICTOR part for your specifications.

Click on the flow restrictor Part Number below for complete part specifications.

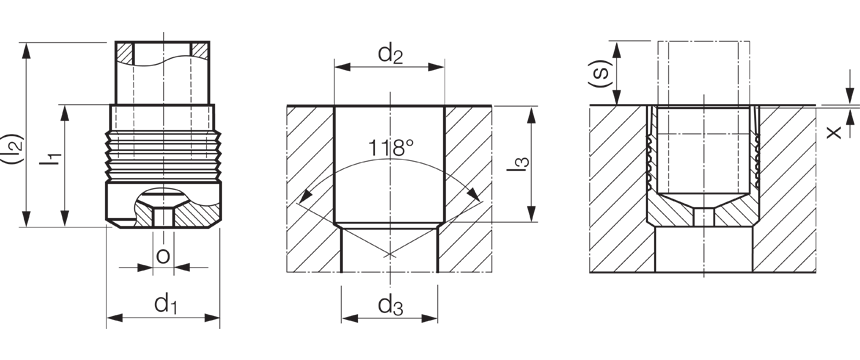

Request a Quote| Part Number | d1 | l1 | [l2 ] ~ Ref. | 0 ±0.025 Orifice Diameter |

d2 +0.10 -0 |

l3 min. | d3 max. |

[s] ~ Ref. | x ±0.3 |

Packaging Unit |

|---|---|---|---|---|---|---|---|---|---|---|

| RE-040-XXX | 4.0 | 4.0 | 6.0 | 0.40 – 1.27 | 4.0 | 3.9 | 3.3 | 2.0 | 0.0 | 100 / 1000 |

| RE-050-XXX | 5.0 | 5.5 | 8.2 | 0.40 – 1.91 | 5.0 | 5.4 | 4.3 | 2.7 | 0.0 | 100 / 1000 |

| RE-060-XXX | 6.0 | 6.5 | 9.9 | 0.40 – 2.54 | 6.0 | 6.4 | 5.3 | 3.4 | 0.0 | 100 / 1000 |

| RE-070-XXX | 7.0 | 7.5 | 11.6 | 0.40 – 3.30 | 7.0 | 7.4 | 6.2 | 4.1 | 0.0 | 100 / 1000 |

| RE-080-XXX | 8.0 | 8.5 | 13.3 | 0.40 – 3.81 | 8.0 | 8.4 | 7.2 | 4.8 | 0.0 | 100 / 1000 |

| RE-090-XXX | 9.0 | 10.0 | 15.5 | 0.40 – 4.32 | 9.0 | 9.9 | 8.2 | 5.5 | 0.0 | 100 / 1000 |

| RE-100-XXX | 10.0 | 11.0 | 17.1 | 0.40 – 4.95 | 10.0 | 10.9 | 9.2 | 6.1 | 0.0 | 50/250 |

Dimensions in millimeters

| Series RE mm | Base Material of the Installation | |||

|---|---|---|---|---|

| High Strength Steel ETG-100 / 44SMn28 AISI 1144 |

Ductile Cast Iron (Dura-Bar®) EN 1563: GJS-450-10 ASTM A536: 65-45-12 |

Aluminum-Alloy AICu4Mg1 / EN AW-2024-T3 AA: 2024 T4/T6* |

Cast Aluminum-Alloy G-AISi7Mg / EN-AC-42100 ASTM/UNS: A356A |

|

| Ø 4 | 120 bar / 1740 psi | 100 bar / 1450 psi | ||

| Ø 5 | 180 bar / 2610 psi | 150 bar / 2175 psi | ||

| Ø 6 | 210 bar / 3045 psi | 150 bar / 2175 psi | ||

| Ø 7 – 8 | 210 bar / 3045 psi | 180 bar / 2610 psi | ||

| Ø 9 – 10 | Please Contact Us for Details | |||

| Max. Allowable Working Pressure = Nominal Pressure *SFC KOENIG’s North American Engineering Department utilizes 2024-T4/T6 as a test base material. |

||||

Operation

Technical Information

- Design Guidelines – wall thickness / distance from edge; required installation lengths, roundness tolerance, and conicity of the bore – view page or downloadable PDF

- Anchorage Principle – view page or downloadable PDF

- Galvanic Corrosion – view page or downloadable PDF

- Technical Information RE – view page or downloadable PDF

- Hardness Conversion Table – view page or downloadable PDF

- Quality Certificates