TECHNICAL INFORMATION - Anchorage Principle

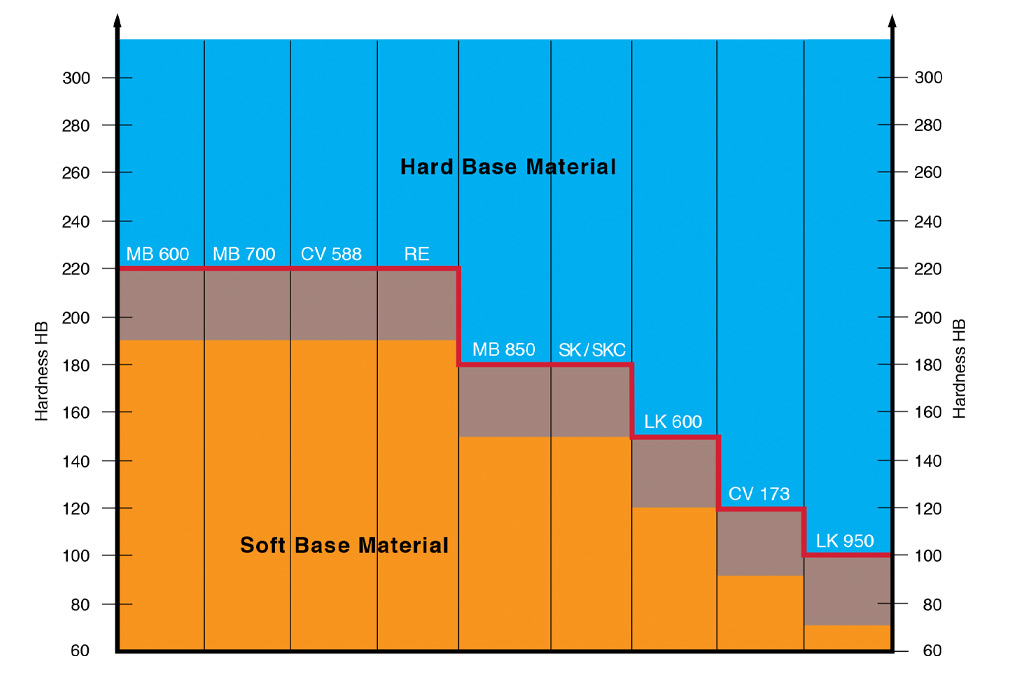

The required bore roughness is directly related to the hardness and the mechanical characteristics of the base material. Depending on the combination of sealing plug and base material, anchorage takes place either by the groove profile of the expander sleeve biting into the base material or on anchorage to the surface roughness of the bore.

Note:

When selecting a KOENIG EXPANDER® the bore roughness must always be adjusted according to the hardness of the base material.

Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB = 30 greater than the base material. If the hardness difference is less, hole roughness of 10 to 30 μm is needed to achieve indicated working pressures.

Anchorage Principle Related to the Base Material

| Base Material Harder than Expander: To achieve the allowable working pressure, anchorage to the bore roughness of the base material is required. Roughness Rz = 10 – 30 μm. | |

| Base Material Softer than Expander: Anchorage to the bore of the base material occurs automatically due to the serrations on the sleeve of the KOENIG EXPANDER® | |

| Transition Zone: To achieve the allowable working pressure, anchorage to the bore roughness of the base material is required. Roughness Rz = 10 to 30 μm. |

|

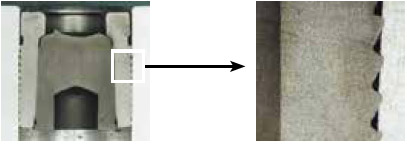

Anchorage due to plug sleeve serrations KOENIG EXPANDER® Series SK / SKC In aluminum-alloy HB = 90 |

|

|

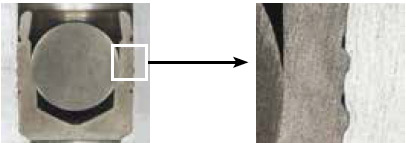

Anchorage due to plug sleeve serrations KOENIG EXPANDER® Series MB 850 In aluminum-alloy HB = 90 |

|

|

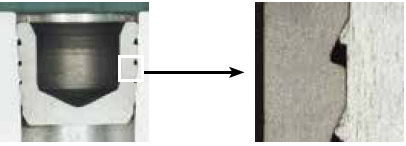

Sufficient anchorage due to plug sleeve serrations KOENIG EXPANDER® Series LK 950 In aluminum-alloy HB = 90 |

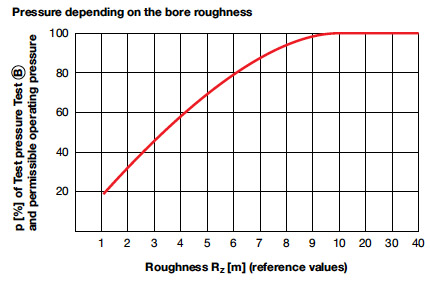

BORE ROUGHNESS REQUIREMENTS

When installing KOENIG EXPANDER(R) plugs in hard base material positive anchoring is not possible. To attain suitable working pressures and anchorage, it is necessary to have a bore roughness of Rz = 10 – 30 μm. At a roughness greater than Rz = 30 μm leakage might occur.

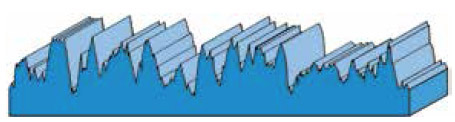

ROUGHNESS PROFILE

Required Roughness Profile – The ideal bore roughness for anchorage is attained by drilling with a twist drill or a core drill.

Undesirable Roughness Profile – By reaming, a one-sided, smooth roughness profile is created. This is not desirable.