Sealing products

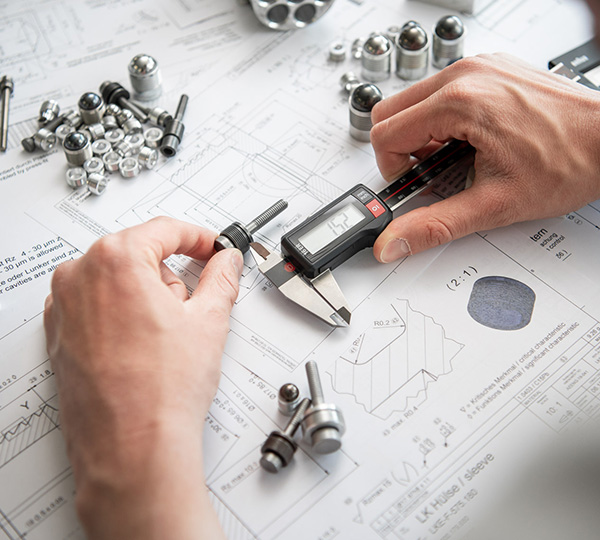

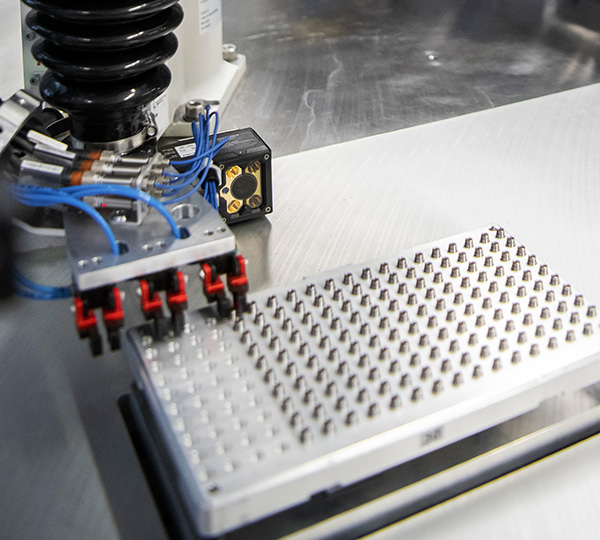

Compared to other expander seal solutions, KOENIG EXPANDER® plugs consistently exceed performance expectations, providing a precise and reliable solution, often at the lowest cost when compared with competitors. These plugs feature a one-piece, easy-to-install design that integrates with automated manufacturing operations, and are available in a wide range of material options and plug sizes.

KOENIG EXPANDER® components tolerate one of the widest temperatures ranges of any expander plug option in the market, with effective operation from -40°C to 150°C (-40°F to 302°F). Standard push-style and pull-style expander plugs can steadily work at pressures up to 450 and 550 bar respectively, and are pressure rated with safety factors to accommodate system shocks and pressure spikes.

The KOENIG EXPANDER® plug is one of the most dependable and customizable expander seals in the market. It can be custom-configured to meet the needs of virtually any application.

Expander Sealing Products

Push Style

Expander Sealing Products

Pull Style

Push-style models require a hole drilled with a counter bore. The plug is dropped into the hole up to the counter bore and then a ball is pressed into a seated shell, which causes serrated grooves to expand into the base material creating a tight, metal-to-metal seal.

For the Pull Style of the KOENIG EXPANDER®, counter-bored holes are required. Pull-style models do not require the hole to be counter-bored and instead use an integrated mandrel to insert the plug into a drilled hole. Since it can be easily aligned, the pull-style plug is often used for angled channels. This style of expander plug is also ideal for applications where holes are on different faces, and for which it’s difficult to move the block for proper orientation.

Series MB

Sleeve: Stainless Steel

Harden Steel Zinc Plated

Ball: Stainless Steel and Bearing Steel

Pressure to Max: 450 bar

Size: 3-22 mm

Series CV

Sleeve: Stainless Steel and Aluminum

Ball: Stainless Steel

Pressure to Max: 450 bar

Size: 3-12 mm

Series SK and SKC

Sleeve:Case Hardening Steel

Mandrel: Heat Treable Steel

Pressure to max: 500 bar

Sizes: 4-10 mm

Series LK

Sleeve: Stainless Steel and Case Hardening Steel

Mandrel: Stainless Steel and Steel

Pressure to Max: 60 bar

Sizes: 4-20 mm