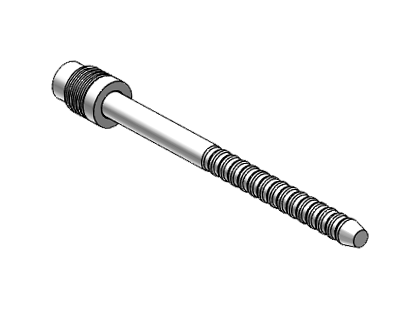

KOENIG EXPANDER® SERIES LK 950 – OVERVIEW

Pull-style expander seals use an integrated mandrel to insert the expander plug into a drilled hole. This type of KOENIG EXPANDER® Series LK 950 plug does not require the hole to be counter-bored, and is often used for angled channels or installations with difficult orientations. They are ideal for installations with space or weight constraints. If you are unsure if the LK 950 expander sealing plug series is the right component for your application, use our Product Selector to identify the best KOENIG EXPANDER part for your specifications.

Material:

Sleeve: Case Hardening Steel, Soft Annealed Gun Finish Mandrel: Steel, Special Oil Film Lubrication

Product SpecificationsPressure PerformanceTechnical DownloadsVideo

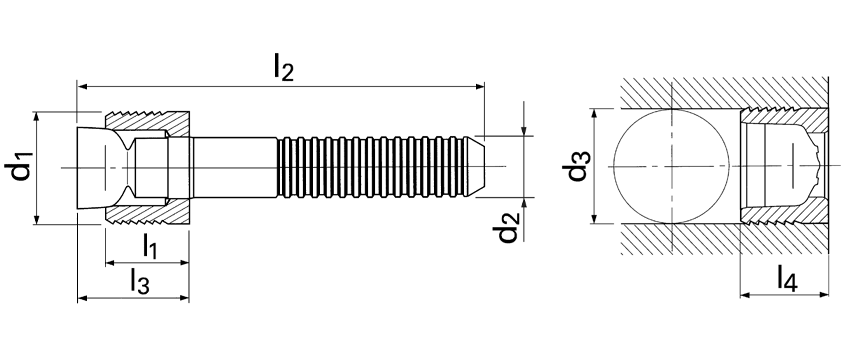

| Product Number | d1 | l1 | d2 | l2 | d3 | l3 max. | L4 Max. (BO) | Packaging Unit | Weight in gram/pcs. | 3D CAD |

|---|---|---|---|---|---|---|---|---|---|---|

| LK 950-040 | 4 | 3.7 | 2.2 | 36 | 4 | 5.5 | 4 | 100 / 1000 | 1.26 | View CAD |

| LK 950-050 | 5 | 4.5 | 3 | 36 | 5 | 6.9 | 4.8 | 100 / 1000 | 2.28 | View CAD |

| LK 950-060 | 6 | 5 | 3.4 | 36 | 6 | 7.7 | 5.3 | 100 / 1000 | 3.12 | View CAD |

| LK 950-070 | 7 | 5.5 | 4.2 | 34 | 7 | 8.5 | 5.8 | 100 / 500 | 4.7 | View CAD |

| LK 950-080 | 8 | 6.5 | 4.3 | 34 | 8 | 9.8 | 6.8 | 100 / 500 | 5.32 | View CAD |

| LK 950-090 | 9 | 6.5 | 4.7 | 34 | 9 | 9.8 | 6.8 | 100 / 500 | 6.53 | View CAD |

| LK 950-100 | 10 | 6.5 | 5.1 | 36 | 10 | 9.8 | 6.8 | 100 / 500 | 8.23 | View CAD |

| LK 950-120 | 12 | 7.5 | 5.9 | 36 | 12 | 11.7 | 7.8 | 100 / 500 | 12.21 | View CAD |

| LK 950-140 | 14 | 8 | 5.9 | 36 | 14 | 12.2 | 8.7 | 100 / 250 | 13.98 | View CAD |

| LK 950-160 | 16 | 10.5 | 5.9 | 42 | 16 | 16.5 | 11.5 | 100 / 250 | 21.17 | View CAD |

| LK 950-180 | 18 | 11 | 6.6 | 50 | 18 | 17.7 | 13 | 100 / 200 | 29.99 | View CAD |

| LK 950-200 | 20 | 11 | 6.6 | 50 | 20 | 17.7 | 13 | 50 / 125 | 34.55 | View CAD |

Dimensions in millimeters

< 280HB the bore tolerance should be 0 / +0.12

≥ 280HB the bore tolerance should be +0.05 / +0.15

| Series LK 950 mm |

Base Material of the Installation | ||||||

|---|---|---|---|---|---|---|---|

| High Strength Steel ETG-100 / 44SMn28 AISI 1144 |

Case Hardened Steel C15Pb/1.0403 ~SAE1015 (10L15) |

Ductile Cast Iron EN 1563: GJS-600-3 ASTM A536: 80-60-03 |

Gray Cast Iron EN 1561:GJL-250 ASTM A48: NO35 |

Aluminum-Alloy AICu4Mg1/ EN AW-2024-T3 AA:2024 T4/T6* |

Aluminum-Alloy AIMgSiPb/ EN AW-6012-T6 AA: 6012-T6 |

Cast Aluminum-Alloy G-AISi7Mg/ EN-AC-42100 ASTM/UNS: A356 |

|

| Ø 4 – 20 | 180 bar / 2.600 psi 60 bar / 850 psi |

||||||

| Proof Pressure Test B Max. allowable Working Pressure = Nominal Pressure *SFC KOENIG’s North American Engineering Department utilizes 2024-T4/T6 as a test base material. |

|||||||

Operation

- Installation Instruction LK PDF

- EXTOOL-030 – Hydraulic/Pneumatic Tool

- EXTOOL-040-1 – Hydraulic/Pneumatic Tool

- EXTOOL-040-2 – Hydraulic/Pneumatic Tool

- EXTOOL-050 – Hydraulic/Pneumatic Tool

- EXTOOL-B-010 – Hydraulic/Pneumatic Tool

Technical Information

- Design Guidelines – wall thickness / distance from edge; required installation lengths, roundness tolerance, and conicity of the bore – view page or downloadable PDF

- Anchorage Principle – view page or downloadable PDF

- Galvanic Corrosion – view page or downloadable PDF

- Technical Information – test pressure, base material / installation requirements, pressure performance – view page or downloadable PDF

- Hardness Conversion Table – view page or downloadable PDF

- Quality Certificates

Pull-style expander seals use an integrated mandrel to insert the expander plug into a drilled hole. This type of KOENIG EXPANDER® Series LK 950 plug does not require the hole to be counter-bored, and is often used for angled channels or installations with difficult orientations. They are ideal for installations with space or weight constraints. If you are unsure if the LK 950 expander sealing plug series is the right component for your application, use our

Pull-style expander seals use an integrated mandrel to insert the expander plug into a drilled hole. This type of KOENIG EXPANDER® Series LK 950 plug does not require the hole to be counter-bored, and is often used for angled channels or installations with difficult orientations. They are ideal for installations with space or weight constraints. If you are unsure if the LK 950 expander sealing plug series is the right component for your application, use our