TECHNICAL INFORMATION - Test Pressure, Base Material / Installation Requirements, Pressure Performance

KOENIG EXPANDER® TEST PRESSURE

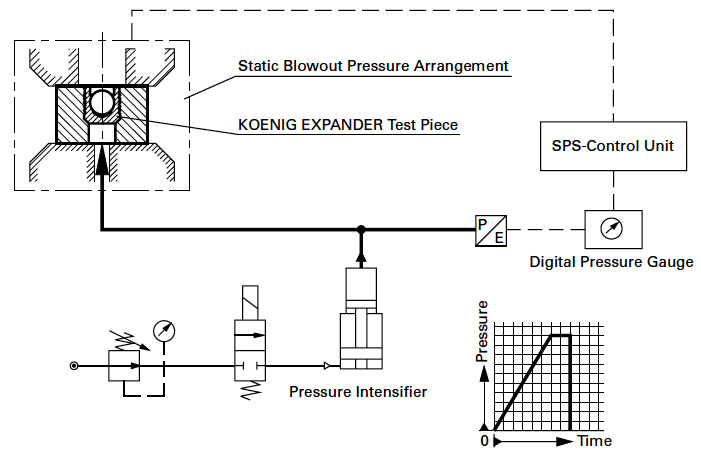

TEST PRESSURE, TEST Ⓐ

The KOENIG EXPANDER® is statically loaded up to burst pressure. This test is performed at SFC KOENIG for functional testing during the production process.

Samples from each production batch are subjected to this functional test.

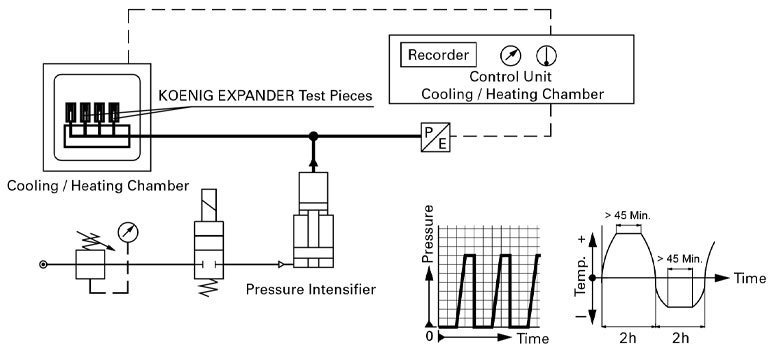

TEST PRESSURE, TEST Ⓑ

The KOENIG EXPANDER® is subjected to a pressure cycling test under varying environmental conditions. The test determines the levels of pressure that can be absorbed by the part by applying intermittent pressure loads and temperature fluctuations to confirm the sealing plug is not squeezed out.

CONDITIONS

- Temperature: > 45 min. at +100°C (Series LK partially at +150°C) / > 45 min. at -40°C

- Pressure: Intermittent, 24 sec. 0 bar / 36 sec. proof pressure (10,000 cycles)

- Duration: 168 hrs (long-term test)

- Bore: Tolerance, roundness and roughness in accordance with standard sheets, plain surface, edge and wall distance according to standard sheet

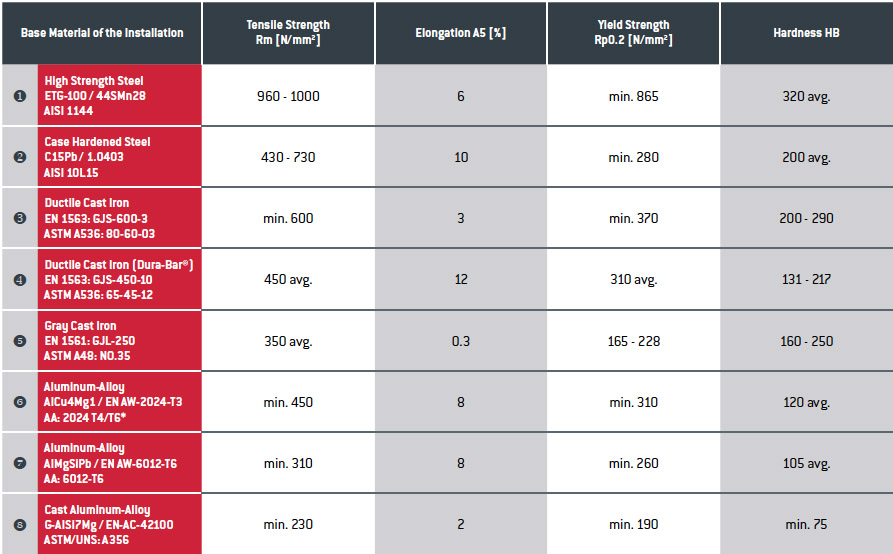

BASE MATERIALS / INSTALLATION REQUIREMENTS

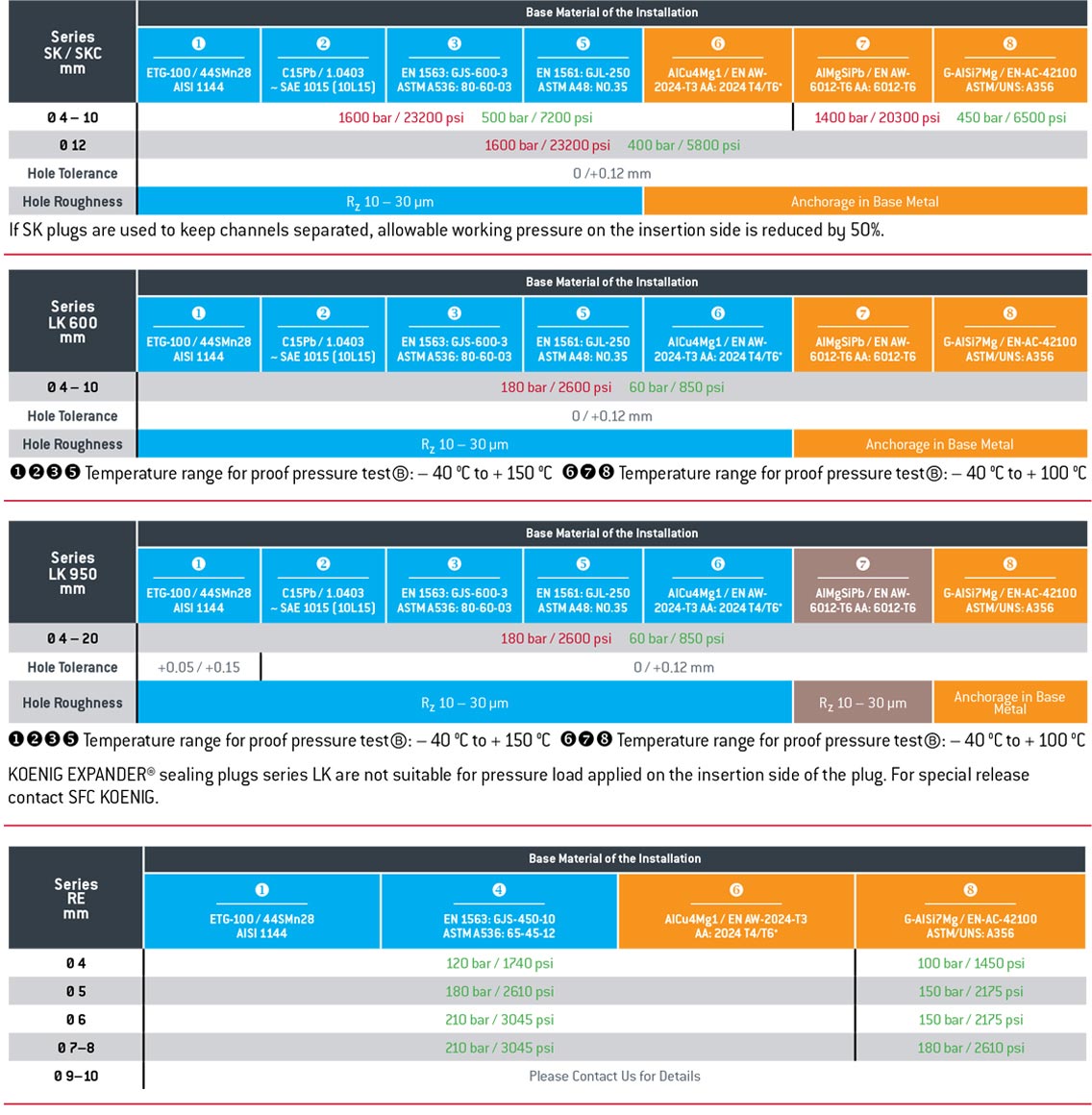

Operating pressures listed can be achieved for the following base materials:

*SFC KOENIG’s North American Engineering Department utilizes 2024-T4/T6 as a test base material.

- Equally high working pressures can also be achieved with base materials with similar mechanical properties. However, compliance must be met for the appropriate installation conditions.

- Applications in high-strength aluminum alloys, magnesium alloys, nonferrous metals and plastics require special consideration and can be developed upon request.

- Applications in base materials with high hardness and hardened materials, require special consideration and can be developed upon request.

- Applications in surface coated materials (zinc plated, anodized …) require special consideration and can be developed upon request.

- For factors affecting pressure performance please see: Anchoring Principle, Surface Finish: Requirements, Design Guidelines

SAFETY MARGIN

The safety margin includes uncontrollable factors. Dynamic loads at nominal pressure, with 106 load cycles and a frequency of 3 –4 Hz have shown that the subsequently measured bursting pressures, are reduced according to Test Ⓐ by 20 % as well as Test Ⓑ.

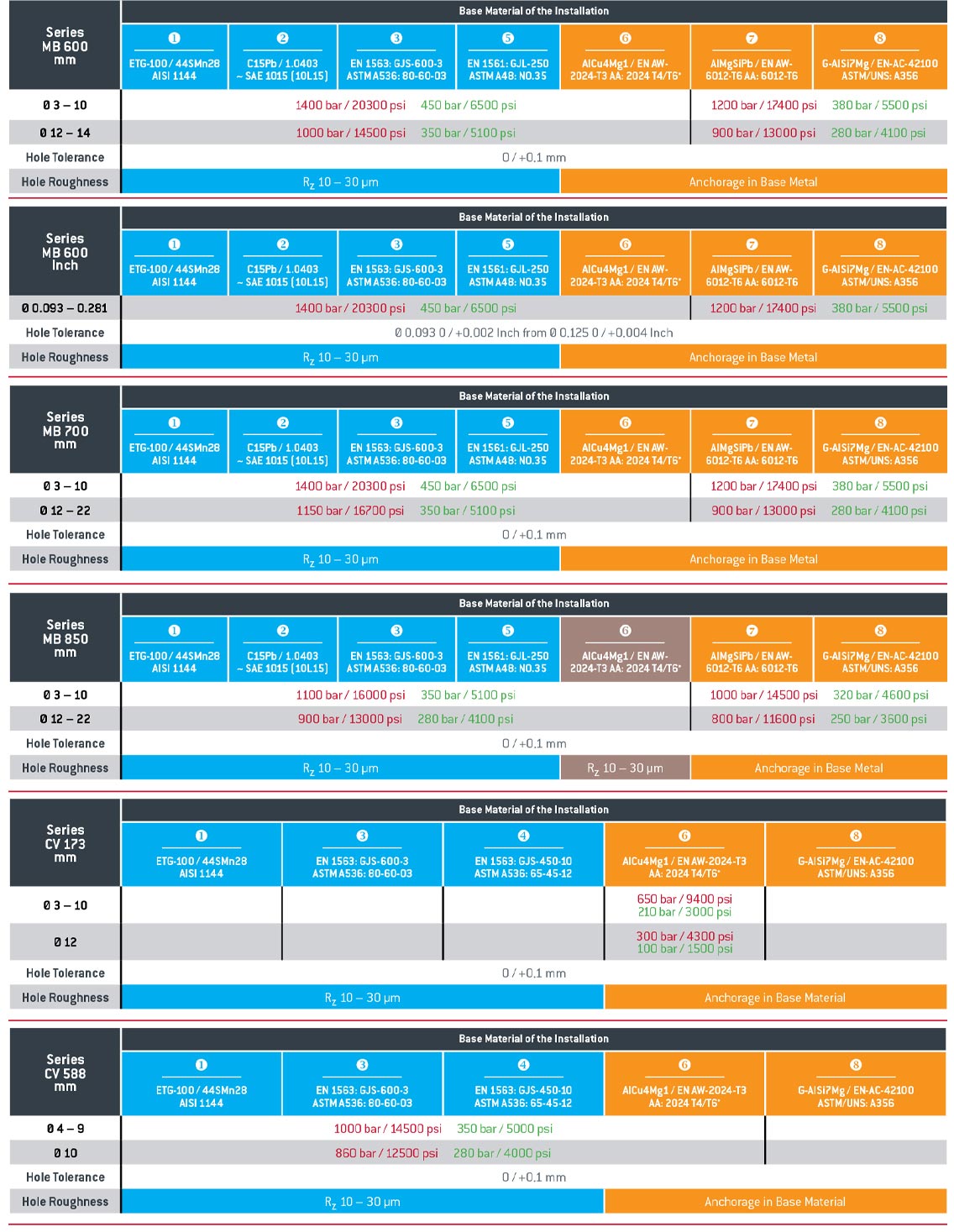

PRESSURE PERFORMANCE

| Base Material Harder than Expander: To achieve the allowable working pressure, anchorage to the bore roughness of the base material is required. Roughness Rz = 10 – 30 μm. | ||

| Base Material Softer than Expander: Anchorage to the bore of the base material occurs automatically due to the serrations on the sleeve of the KOENIG EXPANDER® | ||

| Transition Zone: To achieve the allowable working pressure, anchorage to the bore roughness of the base material is required. Roughness Rz = 10 to 30 μm. |

See Anchorage Principles related to the base materials

Click for downloadable PDF