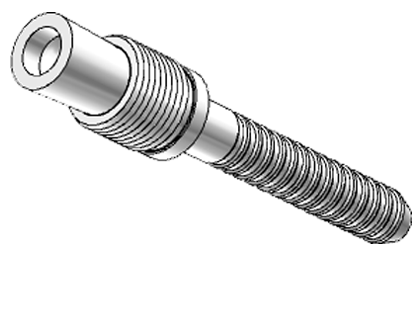

KOENIG EXPANDER® SERIES SK / SKC 550 – OVERVIEW

Pull-style expander seals use an integrated mandrel to insert the expander plug into a drilled hole. The KOENIG EXPANDER® Series SK / SKC 550 plug does not require the hole to be counter-bored, and is often used for angled channels or installations with difficult orientations. They are ideal for installations with space or weight constraints. If you are unsure if the SK / SKC 550 expander sealing plug series is the right component for your application, use our Product Selector to identify the best KOENIG EXPANDER part for your specifications.

Material:

Sleeve: Case Hardening Steel, Gun Metal-Finish Mandrel: Heat Treatable Steel, Special Oil Film Lubrication

Product SpecificationsPressure PerformanceTechnical DownloadsVideo

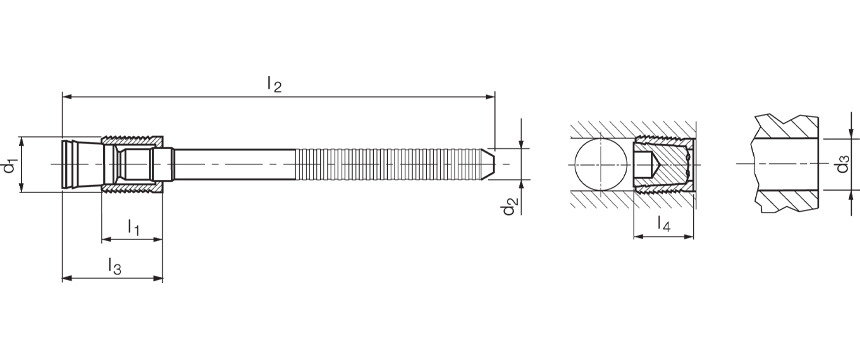

| Product Number | d1 | l1 | d2 | l2 | l3 max. | L4 Max. (BO) | d3 +0.12 / -0 | Packaging Unit | Weight in gram/pcs. | 3D CAD |

|---|---|---|---|---|---|---|---|---|---|---|

| SKC 550-040 | 4 | 4.5 | 2.5 | 39 | 8.6 | 6.5 | 4 | 100 / 1000 | 1.71 | View CAD |

| SKC 550-050 | 5 | 5.5 | 2.80 | 41 | 10.0 | 7.5 | 5 | 100 / 1000 | 2.50 | View CAD |

| SKC 550-060 | 6 | 6.5 | 3.3 | 38 | 12.0 | 8.5 | 6 | 100 / 500 | 3.50 | View CAD |

| SKC 550-070 | 7 | 7.5 | 4.0 | 38 | 13.5 | 9.5 | 7 | 100 / 500 | 5.10 | View CAD |

| SK 550-080 | 8 | 8.5 | 4.2 | 40 | 14.9 | 10.5 | 8 | 100 / 500 | 6.33 | View CAD |

| SK 550-090 | 9 | 9.5 | 4.5 | 43 | 17.1 | 11.5 | 9 | 100 / 250 | 8.23 | View CAD |

| SK 550-100 | 10 | 10.5 | 4.80 | 43 | 19.1 | 13.5 | 10 | 100 / 250 | 10.57 | View CAD |

Dimensions in millimeters”

| Series SK / SKC 550 mm |

Base Material of the Installation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| High Strength Steel ETG-100 / 44SMn28 AISI 11441 |

Case Hardened Steel C15Pb / 1.0403 AISI 10L15 |

Ductile Cast Iron EN 1563: GJS-600-3 ASTM A536: 80-60-03 |

Gray Cast Iron EN 1561: GJL-250 ASTM A48: NO.35 |

Aluminum-Alloy AICu4Mg1 / EN AW-2024-T3 AA: 2024 T4/T6* |

Aluminum-Alloy AIMgSiPb / EN AW-6012-T6 AA: 6012-T6 |

Cast Aluminum-Alloy G-AISi7Mg / EN-AC-42100 ASTM/UNS: A356 |

|||

| Ø 4 – 10 | 1600 bar / 23200 psi 500 bar / 7200 psi |

1400 bar / 20300 psi 450 bar / 6500 psi |

|||||||

| Ø 12 | 1600 bar / 23200 psi 400 bar / 5800 psi |

||||||||

| Proof Pressure Test B Max. allowable Working Pressure = Nominal Pressure *SFC KOENIG’s North American Engineering Department utilizes 2024-T4/T6 as a test base material. |

|||||||||

Operation

- Installation Instruction SK PDF

- Setting Tool SK

- EXTOOL-030 – Hydraulic/Pneumatic Tool

- EXTOOL-040-1 – Hydraulic/Pneumatic Tool

- EXTOOL-040-2 – Hydraulic/Pneumatic Tool

- EXTOOL-050 – Hydraulic/Pneumatic Tool

- EXTOOL-B-010 – Hydraulic/Pneumatic Tool

Technical Information

- Design Guidelines – wall thickness / distance from edge; required installation lengths, roundness tolerance, and conicity of the bore – view page or downloadable PDF

- Anchorage Principle – view page or downloadable PDF

- Galvanic Corrosion – view page or downloadable PDF

- Technical Information – test pressure, base material / installation requirements, pressure performance – view page or downloadable PDF

- Hardness Conversion Table – view page or downloadable PDF

- Quality Certificates

Pull-style expander seals use an integrated mandrel to insert the expander plug into a drilled hole. The KOENIG EXPANDER® Series SK / SKC 550 plug does not require the hole to be counter-bored, and is often used for angled channels or installations with difficult orientations. They are ideal for installations with space or weight constraints. If you are unsure if the SK / SKC 550 expander sealing plug series is the right component for your application, use our

Pull-style expander seals use an integrated mandrel to insert the expander plug into a drilled hole. The KOENIG EXPANDER® Series SK / SKC 550 plug does not require the hole to be counter-bored, and is often used for angled channels or installations with difficult orientations. They are ideal for installations with space or weight constraints. If you are unsure if the SK / SKC 550 expander sealing plug series is the right component for your application, use our