archive.php

Category: News

Quality and Service Focused Throughout the COVID-19 Pandemic

Mon, 07/27/2020

A Quality-Focused Commitment to Serving Customers’ Sealing & Flow Control Needs

Throughout the COVID-19 pandemic, SFC KOENIG® has worked to protect health and safety, adapting processes to best serve customers while providing solutions for new medical applications.

As a global organization with manufacturing locations in Switzerland, Germany, the United States and China, SFC KOENIG has actively supported customers as the effects of COVID-19 spread across the globe.

“All of our manufacturing locations remain open,” stated Tom Ryan, Head of Product Management at SFC KOENIG. “We are so proud of the dedication shown by our team, who quickly adapted to these unprecedented times and continually maintained our complete commitment to quality and excellence.”

The company has modified some of its processes during recent months to help protect the health and safety of employees and visitors, as well as to provide support to customers who have new, remote working situations.

While customers are able to visit SFC KOENIG facilities, and company staff continue to be able to visit customer locations when necessary, the organization has increased its usage of video conferencing for product development support, application reviews, testing and more.

“We’re adapting and remaining flexible,” noted Ryan. “From using shared, interactive 3D CAD models that show our KOENIG EXPANDER® seals in new designs, to presenting testing results for flow control products via video conference, we have been pleased at the customer response. In everything we do we work to serve our customers with superior quality. Usually that is driven by the unsurpassed value of our product line, but now, we are adding to our value even more by working to support people in new ways that are best for their requirements and their preferences.”

As a unit of IDEX corporation, the company has benefitted from guidance on how to maintain operations, adjust process and remain compliant to standards as the pandemic evolved.

Like many modern and technology-driven manufacturers, SFC KOENIG also quickly reacted to the needs of a changing market in recent months.

“While we serve a wide variety of applications, automotive and fluid power is historically a significant portion of our business,” noted Ryan. “However, with COVID-19, there has been an increased demand for medical equipment solutions. It is part of our company’s core value system to prioritize health and safety, and we are always guided by a commitment to act as a responsible global organization. Our team has worked tirelessly to rapidly serve customers with medical application requirements, and I am proud to say that our products were used in critical applications around the world.”

With more than 5 billion parts installed and failure rates less than 1 PPM, SFC KOENIG components are recognized for unsurpassed reliability. This level of quality was an ideal fit for new medical designs and applications, in which performance was critical and operating conditions were often unique.

The company provides expander seals, check valves and flow restrictors for a wide variety of medical assemblies and devices including ventilators, respiratory devices, stretchers, hospital beds and more.

“Quality is at the core of everything we do at SFC KOENIG,” stated Ryan. “It’s in our products, the way we care for others, and how we do our jobs. Customers can continue to rely on our team and our parts for unrivaled excellence, and we look forward to working together to solve every new challenge.”

Wed, 03/18/2020

Changing requirements and on-going advancements in seals, check valves and flow restrictors.

Engine design is in the midst of a revolution. Battery-powered electric motors are replacing internal combustion engines, and support systems are adapting to new requirements. As 2020 marks the 50th anniversary of the KOENIG EXPANDER®, and the invention of the one-piece expansion seal design by the company, SFC KOENIG® is celebrating how engine and automotive design has progressed over the past five decades, and its role in innovations.

“Compared to 50 years ago, design and performance requirements are much more precise,” noted David Ramirez, Application Engineer at SFC KOENIG. “We are proud to have been involved in many significant advancements while maintaining the safety, reliability and engineering ingenuity customers expect from our products.”

In the past five decades, the number of systems viewed as “critical” has expanded. Braking applications and powertrains were often a focus. In contrast, modern designs and electric vehicles (EVs) have strict requirements for sealing and flow control products, which now serve critical roles in motor cases, transmissions, cooling systems and vehicle suspensions.

Installation reliability has always been a requirement. In the 1970’s production lines involved a number of manual operations. A seal or flow control product had to be correctly installed to prevent failure. With SFC KOENIG’s one-piece design, parts have always been easy to install, providing repeatable quality and dependable seating.

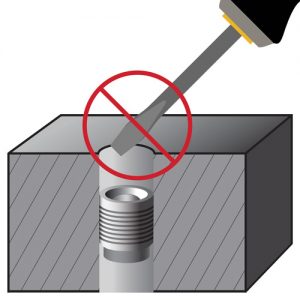

“Our expansion design securely installs and requires no chemicals or sealants,” stated Ramirez. “Components feature a serrated expansion sleeve that expands evenly into bore walls, permanently setting into the base material. There is minimal risk for the contamination and leakage common with commodity-type seals, like cup plugs and threaded screws, which are often-misaligned.”

To meet the needs of today’s operations, SFC KOENIG has adapted its part designs to easily integrate into high-speed and automated assembly lines. Without affecting reliability or effectiveness, parts have been modified making them easier to grab and position in robotic environments.

Parts also require no additional machining processes – such as threading, milling or honing – which not only eliminates manufacturing steps, but also keeps production lines free of debris.

Requirements on part positioning, performance and control have also increased for seals, flow restrictors and check valves since 1970.

“During installation, our parts are distance and force-controlled, have flexible tolerance allowances, and exert even pressures,” stated Ramirez. “That, combined with unrivaled part performance, provides precise flow control and a wide range of sealing capabilities for even highly-unique needs.”

While the company originally developed parts using various steels, lightweighting initiatives require new materials. The design of SFC KOENIG components effectively supports many composites as well as systems produced with additive manufacturing. In addition, aluminum components are now available, and the company is continually developing solutions for new materials, thin walls and complex geometries.

In the past, safety was commonly viewed by the performance of critical systems. SFC KOENIG has one of the industry’s best performance records, with field failure rates less than 1 PPM and over 5 billion parts installed.

As today’s EVs have a number of high-voltage and sensitive assemblies, seals now play a new safety role, preventing access to housings and fluid systems. SFC KOENIG components are tamper-proof and limit access by untrained users without significant, and visible damage, protecting people and preventing false warranty claims.

“At every stage of the industry and in so many innovations, SFC KOENIG parts are there,” noted Ramirez, “and we are actively working with some of the world’s largest manufacturers on cutting-edge designs. While our products and applications have advanced during the last 50 years, we remain committed to supporting customers with unrivaled performance, safety and reliability. We are excited for the future, and to be part of it.”

SFC KOENIG® is celebrating the 50th anniversary of the KOENIG EXPANDER®, and is the original inventor of the one-piece, expansion seal design.

Thu, 01/16/2020

SFC KOENIG®, a Unit of IDEX Corporation, and a leading global supplier of sealing and flow control components, is pleased to announce that its Chinese branch has moved into a new facility. The larger location allows for increased integration with IDEX China while also providing an expanded manufacturing space to support growth.

One of four main global facilities, SFC KOENIG Asia provides engineering, customer service and manufacturing capabilities and offers the company’s line of KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® flow orifices and KOENIG CHECK VALVE® components.

“The expansion of our Chinese location reflects our growing position in Chinese, Japanese and Korean automotive and fluid power markets,” noted Tom Ryan, Head of Product Management at SFC KOENIG. “While the integration of this branch into an IDEX facility will allow for a number of operational benefits, the larger manufacturing space and state-of-the-art infrastructure will help increase capabilities and output.”

The new facility is located in Xiangcheng District, Suzhou, in Jiangsu Province. The campus also houses a number of IDEX Corporation business units, allowing for streamlined support of legal, compliance, human resources and IT functions.

SFC KOENIG®, a Unit of IDEX Corporation, and a leading global supplier of sealing and flow control components, is pleased to announce that its Chinese branch has moved into a new facility. The larger location allows for increased integration with IDEX China while also providing an expanded manufacturing space to support growth.

One of four main global facilities, SFC KOENIG Asia provides engineering, customer service and manufacturing capabilities and offers the company’s line of KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® flow orifices and KOENIG CHECK VALVE® components.

“The expansion of our Chinese location reflects our growing position in Chinese, Japanese and Korean automotive and fluid power markets,” noted Tom Ryan, Head of Product Management at SFC KOENIG. “While the integration of this branch into an IDEX facility will allow for a number of operational benefits, the larger manufacturing space and state-of-the-art infrastructure will help increase capabilities and output.”

The new facility is located in Xiangcheng District, Suzhou, in Jiangsu Province. The campus also houses a number of IDEX Corporation business units, allowing for streamlined support of legal, compliance, human resources and IT functions.

Thu, 04/05/2018

SFC KOENIG is pleased to announce the appointment of Deniz Bütüner as President and General Manager of the company’s North and South American branch.

Ms. Bütüner brings to the position more than twenty years of experience at industrial companies, with a specialized expertise in shaping growth, go-to-market strategies, business development, and new product development. In her most recent position at SFC KOENIG, as the General Manager of Distribution Businesses and Strategic Marketing, Ms. Bütüner oversaw distribution sales channels, new business development, and product management for operations in the United States, Japan, China, India, Europe and beyond.

“I’m excited at the opportunity to lead the division that is responsible for the United States, Canada, Mexico, Central and South America, and to help shape the growth of the SFC KOENIG brand,” noted Bütüner. “In addition to recent production expansions at our North Haven facility, we are expanding our capabilities and customer base, and I look forward to meeting many of our customers personally as we introduce new initiatives.”

Ms. Bütüner earned a bachelor’s degree in business administration and later earned her Global Executive MBA from TRIUM, an alliance of New York University’s Stern School of Business, The London School of Economics and Political Science and HEC School of Management in Paris. Ms. Bütüner speaks five languages, including English, French, and Spanish, and has successfully led multi-cultural teams across continents for a variety of large-scale projects.

Previously, Ms. Bütüner worked out of the company’s headquarters in Zurich, Switzerland, but has recently relocated to Connecticut to take on her new role.

SFC KOENIG is pleased to announce the appointment of Deniz Bütüner as President and General Manager of the company’s North and South American branch.

Ms. Bütüner brings to the position more than twenty years of experience at industrial companies, with a specialized expertise in shaping growth, go-to-market strategies, business development, and new product development. In her most recent position at SFC KOENIG, as the General Manager of Distribution Businesses and Strategic Marketing, Ms. Bütüner oversaw distribution sales channels, new business development, and product management for operations in the United States, Japan, China, India, Europe and beyond.

“I’m excited at the opportunity to lead the division that is responsible for the United States, Canada, Mexico, Central and South America, and to help shape the growth of the SFC KOENIG brand,” noted Bütüner. “In addition to recent production expansions at our North Haven facility, we are expanding our capabilities and customer base, and I look forward to meeting many of our customers personally as we introduce new initiatives.”

Ms. Bütüner earned a bachelor’s degree in business administration and later earned her Global Executive MBA from TRIUM, an alliance of New York University’s Stern School of Business, The London School of Economics and Political Science and HEC School of Management in Paris. Ms. Bütüner speaks five languages, including English, French, and Spanish, and has successfully led multi-cultural teams across continents for a variety of large-scale projects.

Previously, Ms. Bütüner worked out of the company’s headquarters in Zurich, Switzerland, but has recently relocated to Connecticut to take on her new role.

Fri, 11/10/2017

SFC KOENIG has increased its North American production capabilities by adding manufacturing equipment for KOENIG EXPANDER pull-style plugs in its North Haven, Connecticut facility.

“I’m excited to announce the installation of this new production machinery,” said Tom Ryan, Head of Product Management at SFC KOENIG. “Our current manufacturing operations produce the majority of push-style expander plugs shipped to North America, and this expansion allows the company to reduce lead times and meet increasing demand for a wider range of domestically-supplied components.”

The new equipment was custom built for SFC KOENIG and utilizes proven designs already in operation in the company’s Swiss production facility. North American-based production will include SK and LK series KOENIG EXPANDERS, as well as custom expander plugs developed for customer-specific requirements. The expansion of KOENIG EXPANDER manufacturing in North America will allow SFC KOENIG to respond to NAFTA-based customer orders more quickly as well as strengthen the company’s position in the market.

SFC KOENIG has increased its North American production capabilities by adding manufacturing equipment for KOENIG EXPANDER pull-style plugs in its North Haven, Connecticut facility.

“I’m excited to announce the installation of this new production machinery,” said Tom Ryan, Head of Product Management at SFC KOENIG. “Our current manufacturing operations produce the majority of push-style expander plugs shipped to North America, and this expansion allows the company to reduce lead times and meet increasing demand for a wider range of domestically-supplied components.”

The new equipment was custom built for SFC KOENIG and utilizes proven designs already in operation in the company’s Swiss production facility. North American-based production will include SK and LK series KOENIG EXPANDERS, as well as custom expander plugs developed for customer-specific requirements. The expansion of KOENIG EXPANDER manufacturing in North America will allow SFC KOENIG to respond to NAFTA-based customer orders more quickly as well as strengthen the company’s position in the market.

Thu, 09/17/2015

1. SFC KOENIG is the leader of sealing technology, especially for the auto industry – could you introduce briefly your products for automotive?

Our products take care of safety and control of all sorts of components related to fluid systems, starting with hydraulics, but also fuel systems, cooling systems, etc. Engineers of our customers design-in our products with the help of our specialists. Our solutions command highest in class performance and quality.

2. How should one define a good sealing solution? What requirements are always a top priority?

Sealing solution should make sure to offer lifetime safety. Therefore our specialists work closely with customers to qualify our solutions in the specific application and requirements of the client. Further it should offer an advantage from the Total Cost of Ownership point of view. SFC KOENIG has the broadest product line in the industry and can offer the optimal solution. SFC KOENIG has more than 40 years of experience in sealing solutions, with a long in-field quality performance below 1 ppm.

3. How does sealing impact on the quality of braking, oil injection, engines and transmission?

First and foremost: safety and reducing environmental impact. Additionally, these products are critical for proper system function. Design engineers of our customers can simplify and improve the designs of components. They can downsize and reduce weight, but still maintain high level of safety requirements.

4. What are the SFC KOENIG product requirements on the bore tolerance and roughness?

Our customers can chose a higher tolerance range in comparison to other solutions, which sometimes has an important impact on costs, while still providing a superior sealing solution.

5. Compared with classical sealing solutions, what are advantages of SFC KOENIG products?

Safety in terms of sealing, as these are engineered solutions; lifetime sealing adapted to the customer application; better automation of sealing assembly, downsizing of components, etc.

6. As I am aware, SFC KOENIG also has unique products for high pressure common rail. Could you share more details on these products?

We have a range of high pressure sealing solutions which are widely used for fuel injection systems. Working pressure above 2000 bar have been safely implemented in the field for many years.

7. Flow control is another business to SFC, what products are available to these markets?

We have introduced a range of micro valves for the auto industry. Our well-known solutions for Restrictor / nozzle are tested intensively by Chinese engineers.

8. Would SFC work with customers to innovate customized products?

Of course. A certain portion of our volume are customized solutions, based on our well-established product line. Customized solutions can be valuable for our customers. Having more than 5 billion sealing products in the field in many applications, our specialists offer their expertise to our customers to optimize their designs with highest safety standards.

9. The fourth Industrial Revolution is approaching, especially for auto industry, what are SFC KOENIG long-term plans?

SFC KOENIG will continue to serve our clients in the auto industry with unmatched quality and reliability of products, solutions, services and innovations.

10. What well-known customers does SFC serve?

Practically all well-known OEMS and tier 1 and 2 companies are our customers.

1. SFC KOENIG is the leader of sealing technology, especially for the auto industry – could you introduce briefly your products for automotive?

Our products take care of safety and control of all sorts of components related to fluid systems, starting with hydraulics, but also fuel systems, cooling systems, etc. Engineers of our customers design-in our products with the help of our specialists. Our solutions command highest in class performance and quality.

2. How should one define a good sealing solution? What requirements are always a top priority?

Sealing solution should make sure to offer lifetime safety. Therefore our specialists work closely with customers to qualify our solutions in the specific application and requirements of the client. Further it should offer an advantage from the Total Cost of Ownership point of view. SFC KOENIG has the broadest product line in the industry and can offer the optimal solution. SFC KOENIG has more than 40 years of experience in sealing solutions, with a long in-field quality performance below 1 ppm.

3. How does sealing impact on the quality of braking, oil injection, engines and transmission?

First and foremost: safety and reducing environmental impact. Additionally, these products are critical for proper system function. Design engineers of our customers can simplify and improve the designs of components. They can downsize and reduce weight, but still maintain high level of safety requirements.

4. What are the SFC KOENIG product requirements on the bore tolerance and roughness?

Our customers can chose a higher tolerance range in comparison to other solutions, which sometimes has an important impact on costs, while still providing a superior sealing solution.

5. Compared with classical sealing solutions, what are advantages of SFC KOENIG products?

Safety in terms of sealing, as these are engineered solutions; lifetime sealing adapted to the customer application; better automation of sealing assembly, downsizing of components, etc.

6. As I am aware, SFC KOENIG also has unique products for high pressure common rail. Could you share more details on these products?

We have a range of high pressure sealing solutions which are widely used for fuel injection systems. Working pressure above 2000 bar have been safely implemented in the field for many years.

7. Flow control is another business to SFC, what products are available to these markets?

We have introduced a range of micro valves for the auto industry. Our well-known solutions for Restrictor / nozzle are tested intensively by Chinese engineers.

8. Would SFC work with customers to innovate customized products?

Of course. A certain portion of our volume are customized solutions, based on our well-established product line. Customized solutions can be valuable for our customers. Having more than 5 billion sealing products in the field in many applications, our specialists offer their expertise to our customers to optimize their designs with highest safety standards.

9. The fourth Industrial Revolution is approaching, especially for auto industry, what are SFC KOENIG long-term plans?

SFC KOENIG will continue to serve our clients in the auto industry with unmatched quality and reliability of products, solutions, services and innovations.

10. What well-known customers does SFC serve?

Practically all well-known OEMS and tier 1 and 2 companies are our customers.

Mon, 02/17/2014

In April 2014, KVT-Koenig became SFC KOENIG. This is the result of the sale of our Fastening Division to the Bossard Group in October 2012.

Our name and logo are different, but our focus and commitment to provide the highest quality engineered solutions for sealing and flow control remains unchanged. The SFC KOENIG name and our well-known product brands, KOENIG EXPANDER and KOENIG RESTRICTOR, support our mission to be the Leader in Sealing and Flow Control Technology.

SFC KOENIG carries with it the over 85 year history of KVT-Koenig:

In April 2014, KVT-Koenig became SFC KOENIG. This is the result of the sale of our Fastening Division to the Bossard Group in October 2012.

Our name and logo are different, but our focus and commitment to provide the highest quality engineered solutions for sealing and flow control remains unchanged. The SFC KOENIG name and our well-known product brands, KOENIG EXPANDER and KOENIG RESTRICTOR, support our mission to be the Leader in Sealing and Flow Control Technology.

SFC KOENIG carries with it the over 85 year history of KVT-Koenig:

- The original inventor of the one-piece, metal to metal sealing solution over 40 years ago

- ISO/TS 16949, ISO 9001 and ISO 14001 Certified

- Over 5 billion installations

- 0.5 PPM