archive.php

Kategorie: News

Quality and Service Focused Throughout the COVID-19 Pandemic

Mon, 07/27/2020

A Quality-Focused Commitment to Serving Customers’ Sealing & Flow Control Needs

Throughout the COVID-19 pandemic, SFC KOENIG® has worked to protect health and safety, adapting processes to best serve customers while providing solutions for new medical applications.

As a global organization with manufacturing locations in Switzerland, Germany, the United States and China, SFC KOENIG has actively supported customers as the effects of COVID-19 spread across the globe.

“All of our manufacturing locations remain open,” stated Tom Ryan, Head of Product Management at SFC KOENIG. “We are so proud of the dedication shown by our team, who quickly adapted to these unprecedented times and continually maintained our complete commitment to quality and excellence.”

The company has modified some of its processes during recent months to help protect the health and safety of employees and visitors, as well as to provide support to customers who have new, remote working situations.

While customers are able to visit SFC KOENIG facilities, and company staff continue to be able to visit customer locations when necessary, the organization has increased its usage of video conferencing for product development support, application reviews, testing and more.

“We’re adapting and remaining flexible,” noted Ryan. “From using shared, interactive 3D CAD models that show our KOENIG EXPANDER® seals in new designs, to presenting testing results for flow control products via video conference, we have been pleased at the customer response. In everything we do we work to serve our customers with superior quality. Usually that is driven by the unsurpassed value of our product line, but now, we are adding to our value even more by working to support people in new ways that are best for their requirements and their preferences.”

As a unit of IDEX corporation, the company has benefitted from guidance on how to maintain operations, adjust process and remain compliant to standards as the pandemic evolved.

Like many modern and technology-driven manufacturers, SFC KOENIG also quickly reacted to the needs of a changing market in recent months.

“While we serve a wide variety of applications, automotive and fluid power is historically a significant portion of our business,” noted Ryan. “However, with COVID-19, there has been an increased demand for medical equipment solutions. It is part of our company’s core value system to prioritize health and safety, and we are always guided by a commitment to act as a responsible global organization. Our team has worked tirelessly to rapidly serve customers with medical application requirements, and I am proud to say that our products were used in critical applications around the world.”

With more than 5 billion parts installed and failure rates less than 1 PPM, SFC KOENIG components are recognized for unsurpassed reliability. This level of quality was an ideal fit for new medical designs and applications, in which performance was critical and operating conditions were often unique.

The company provides expander seals, check valves and flow restrictors for a wide variety of medical assemblies and devices including ventilators, respiratory devices, stretchers, hospital beds and more.

“Quality is at the core of everything we do at SFC KOENIG,” stated Ryan. “It’s in our products, the way we care for others, and how we do our jobs. Customers can continue to rely on our team and our parts for unrivaled excellence, and we look forward to working together to solve every new challenge.”

Wed, 03/18/2020

Changing requirements and on-going advancements in seals, check valves and flow restrictors.

Engine design is in the midst of a revolution. Battery-powered electric motors are replacing internal combustion engines, and support systems are adapting to new requirements. As 2020 marks the 50th anniversary of the KOENIG EXPANDER®, and the invention of the one-piece expansion seal design by the company, SFC KOENIG® is celebrating how engine and automotive design has progressed over the past five decades, and its role in innovations.

“Compared to 50 years ago, design and performance requirements are much more precise,” noted David Ramirez, Application Engineer at SFC KOENIG. “We are proud to have been involved in many significant advancements while maintaining the safety, reliability and engineering ingenuity customers expect from our products.”

In the past five decades, the number of systems viewed as “critical” has expanded. Braking applications and powertrains were often a focus. In contrast, modern designs and electric vehicles (EVs) have strict requirements for sealing and flow control products, which now serve critical roles in motor cases, transmissions, cooling systems and vehicle suspensions.

Installation reliability has always been a requirement. In the 1970’s production lines involved a number of manual operations. A seal or flow control product had to be correctly installed to prevent failure. With SFC KOENIG’s one-piece design, parts have always been easy to install, providing repeatable quality and dependable seating.

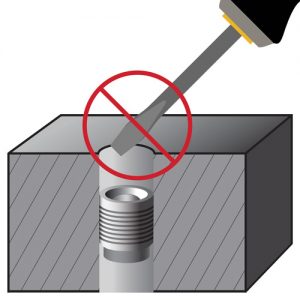

“Our expansion design securely installs and requires no chemicals or sealants,” stated Ramirez. “Components feature a serrated expansion sleeve that expands evenly into bore walls, permanently setting into the base material. There is minimal risk for the contamination and leakage common with commodity-type seals, like cup plugs and threaded screws, which are often-misaligned.”

To meet the needs of today’s operations, SFC KOENIG has adapted its part designs to easily integrate into high-speed and automated assembly lines. Without affecting reliability or effectiveness, parts have been modified making them easier to grab and position in robotic environments.

Parts also require no additional machining processes – such as threading, milling or honing – which not only eliminates manufacturing steps, but also keeps production lines free of debris.

Requirements on part positioning, performance and control have also increased for seals, flow restrictors and check valves since 1970.

“During installation, our parts are distance and force-controlled, have flexible tolerance allowances, and exert even pressures,” stated Ramirez. “That, combined with unrivaled part performance, provides precise flow control and a wide range of sealing capabilities for even highly-unique needs.”

While the company originally developed parts using various steels, lightweighting initiatives require new materials. The design of SFC KOENIG components effectively supports many composites as well as systems produced with additive manufacturing. In addition, aluminum components are now available, and the company is continually developing solutions for new materials, thin walls and complex geometries.

In the past, safety was commonly viewed by the performance of critical systems. SFC KOENIG has one of the industry’s best performance records, with field failure rates less than 1 PPM and over 5 billion parts installed.

As today’s EVs have a number of high-voltage and sensitive assemblies, seals now play a new safety role, preventing access to housings and fluid systems. SFC KOENIG components are tamper-proof and limit access by untrained users without significant, and visible damage, protecting people and preventing false warranty claims.

“At every stage of the industry and in so many innovations, SFC KOENIG parts are there,” noted Ramirez, “and we are actively working with some of the world’s largest manufacturers on cutting-edge designs. While our products and applications have advanced during the last 50 years, we remain committed to supporting customers with unrivaled performance, safety and reliability. We are excited for the future, and to be part of it.”

SFC KOENIG® is celebrating the 50th anniversary of the KOENIG EXPANDER®, and is the original inventor of the one-piece, expansion seal design.

Thu, 01/16/2020

SFC KOENIG®, a Unit of IDEX Corporation, and a leading global supplier of sealing and flow control components, is pleased to announce that its Chinese branch has moved into a new facility. The larger location allows for increased integration with IDEX China while also providing an expanded manufacturing space to support growth.

One of four main global facilities, SFC KOENIG Asia provides engineering, customer service and manufacturing capabilities and offers the company’s line of KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® flow orifices and KOENIG CHECK VALVE® components.

“The expansion of our Chinese location reflects our growing position in Chinese, Japanese and Korean automotive and fluid power markets,” noted Tom Ryan, Head of Product Management at SFC KOENIG. “While the integration of this branch into an IDEX facility will allow for a number of operational benefits, the larger manufacturing space and state-of-the-art infrastructure will help increase capabilities and output.”

The new facility is located in Xiangcheng District, Suzhou, in Jiangsu Province. The campus also houses a number of IDEX Corporation business units, allowing for streamlined support of legal, compliance, human resources and IT functions.

SFC KOENIG®, a Unit of IDEX Corporation, and a leading global supplier of sealing and flow control components, is pleased to announce that its Chinese branch has moved into a new facility. The larger location allows for increased integration with IDEX China while also providing an expanded manufacturing space to support growth.

One of four main global facilities, SFC KOENIG Asia provides engineering, customer service and manufacturing capabilities and offers the company’s line of KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® flow orifices and KOENIG CHECK VALVE® components.

“The expansion of our Chinese location reflects our growing position in Chinese, Japanese and Korean automotive and fluid power markets,” noted Tom Ryan, Head of Product Management at SFC KOENIG. “While the integration of this branch into an IDEX facility will allow for a number of operational benefits, the larger manufacturing space and state-of-the-art infrastructure will help increase capabilities and output.”

The new facility is located in Xiangcheng District, Suzhou, in Jiangsu Province. The campus also houses a number of IDEX Corporation business units, allowing for streamlined support of legal, compliance, human resources and IT functions.

Mon, 02/17/2014 – 01:00

Im April 2014 wurde KVT-Koenig zu SFC KOENIG. Grund hierfür war der Verkauf unseres Bereichs Verbindungstechnologie an die Bossard Group im Oktober 2012.

Wir haben unseren Namen und unser Logo geändert, aber an unserem Fokus und unserem Bestreben, erstklassige Engineering-Lösungen im Bereich Dichtungstechnologie und Regelsysteme bereitzustellen, hat sich nichts geändert. Der Name SFC KOENIG und unsere renommierten Produktmarken KOENIG-EXPANDER und KOENIG-RESTRICTOR unterstützen uns in unserem Bestreben, führender Anbieter im Bereich Dichtungstechnologie und Regelsysteme zu sein.

SFC KOENIG verkörpert mehr als 85 Jahre Geschichte von KVT-Koenig:

Im April 2014 wurde KVT-Koenig zu SFC KOENIG. Grund hierfür war der Verkauf unseres Bereichs Verbindungstechnologie an die Bossard Group im Oktober 2012.

Wir haben unseren Namen und unser Logo geändert, aber an unserem Fokus und unserem Bestreben, erstklassige Engineering-Lösungen im Bereich Dichtungstechnologie und Regelsysteme bereitzustellen, hat sich nichts geändert. Der Name SFC KOENIG und unsere renommierten Produktmarken KOENIG-EXPANDER und KOENIG-RESTRICTOR unterstützen uns in unserem Bestreben, führender Anbieter im Bereich Dichtungstechnologie und Regelsysteme zu sein.

SFC KOENIG verkörpert mehr als 85 Jahre Geschichte von KVT-Koenig:

- Ursprünglicher Erfinder der Dichtungslösungen für Metallverbindungen vor über 40 Jahren

- ISO/TS 16949, ISO 9001 und ISO 14001 zertifiziert

- mehr als 3 Milliarden installierte Teile

- 0,5 ppm

Thu, 09/17/2015 – 10:46

1、 SFC KOENIG ist eines der führenden Unternehmen für Dichtungstechnologien, insbesondere für die Automobilindustrie – könnten Sie uns kurz Ihre Produkte für die Automobilbranche vorstellen?

Unsere Produkte dienen der Sicherheit und Steuerung aller Arten von Komponenten in Fluidsystemen, wie etwa in hydraulischen Anlagen, Kraftstoffsystemen oder Kühlkreisläufen.

Die Ingenieure unserer Kunden arbeiten zusammen mit unseren Spezialisten an der Entwicklung unserer Produkte.

Unsere Lösungen entsprechen allerhöchsten Maßstäben an die Leistungsfähigkeit und Qualität.

2、 Wie sollte eine gute Lösung einer Abdichtung definiert werden?

Welche Anforderungen sind immer von größter Bedeutung?

Dichtungslösungen sollten über ihre gesamte Lebensdauer hinweg Sicherheit bieten.

Daher arbeiten unsere Spezialisten eng mit unseren Kunden zusammen, damit unsere Lösungen für die spezifische Anwendung geeignet sind und die Anforderungen des Kunden erfüllen.

Außerdem sollte sie aus der Perspektive der Gesamtbetriebskosten einen eindeutigen Vorteil bieten.

SFC KOENIG verfügt über die brancheweit größte Produktpalette und kann daher die optimale Lösung anbieten.

SFC KOENIG blickt auf mehr als 40 Jahre Erfahrung mit Dichtungslösungen zurück – bei einer Ausfallquote im tatsächlichen Betrieb von weniger als 1 pro 1 Million (1 ppm).

3、 Wie wirken sich die Abdichtungen auf das Bremsverhalten, die Öleinspeisung, die Motoren und das Getriebe aus?

In erster Linie:

Sicherheit und Reduzierung der Auswirkungen auf die Umwelt.

Außerdem sind diese Produkte wichtig für eine ordnungsgemäße Funktion des Systems.

Die Konstruktionstechniker unserer Kunden können die Bauarten der Komponenten vereinfachen und verbessern.

Sie können die Größe und das Gewicht reduzieren, während ein hohes Maß an Sicherheit gewährleistet bleibt.

4、 Wie lauten die Produktanforderungen von SFC KOENIG hinsichtlich der Bohrungstoleranzen und der Rauheit?

Unsere Kunden können unter Beibehaltung einer überragenden Dichtheit einen höheren Toleranzbereich wählen, als dies bei anderen Lösungen der Fall ist, was eine wichtige Auswirkung auf die Kosten hat.

5、 Wo liegen im Vergleich zu herkömmlichen Dichtungslösungen die Vorteile der Produkte von SFC KOENIG?

Sicherheit in Bezug auf die Abdichtung, denn dies sind kundenspezifische Lösungen; lebenslange Abdichtung, die auf die Anwendung des Kunden zugeschnitten ist; bessere Automatisierung der Dichtungsmontage, Verkleinerung der Komponenten usw.

6、 Ich habe gehört, dass SFC KOENIG außerdem einzigartige Produkte für die Common-Rail-Einspritzung führt.

Können Sie etwas zu diesen Produkten sagen?

Wir haben eine Reihe von Dichtungstechnologien für Hochdruckbereiche, die in hohem Umfang bei Kraftstoffeinspritzsystemen eingesetzt werden.

Mit einem Arbeitsdruck von mehr als 2.000 bar haben sich diese Produkte in der Branche bereits vor vielen Jahren gut etabliert.

7、 Durchflusssteuerungen sind ein weiterer Geschäftsbereich von SFC. Welche Produkte haben Sie hier im Angebot?

Wir haben eine Reihe von Mikroventilen für die Automobilindustrie eingeführt.

Unsere bekannten Lösungen für Drosseln/Düsen werden intensiv von chinesischen Ingenieuren getestet.

8、 Würde SFC mit Kunden zusammenarbeiten, um kundenspezifische Produkte zu entwickeln?

Natürlich.

Ein gewisser Anteil unserer Fertigung besteht aus kundenspezifischen Lösungen, die auf unserer bewährten Produktlinie aufbauen.

Kundenspezifische Lösungen können für unsere Kunden einen Wert darstellen.

Mit mehr als 3 Milliarden gelieferter Dichtungsprodukte für zahlreiche Anwendungsgebiete verfügen unsere Spezialisten über die nötige Erfahrung, um gemeinsam mit unseren Kunden Konstruktionen zu optimieren, die den höchsten Sicherheitsstandards entsprechen.

9、Die Vierte Industrielle Revolution ist bereits in Sicht, insbesondere in der Automobilindustrie. Wie sehen die langfristigen Pläne von SFC KOENIG aus?

SFC KOENIG wird weiterhin für seine Kunden in der Automobilindustrie da sein, und das mit unerreichter Qualität und Zuverlässigkeit der Produkte, Lösungen, Dienstleistungen und Innovationen.

10、 Welche großen Namen befinden sich unter den Kunden von SFC?

Praktisch alle bekannten Originalersatzteilhersteller sowie Unternehmen der Ebenen Tier 1 und Tier 2.

1、 SFC KOENIG ist eines der führenden Unternehmen für Dichtungstechnologien, insbesondere für die Automobilindustrie – könnten Sie uns kurz Ihre Produkte für die Automobilbranche vorstellen?

Unsere Produkte dienen der Sicherheit und Steuerung aller Arten von Komponenten in Fluidsystemen, wie etwa in hydraulischen Anlagen, Kraftstoffsystemen oder Kühlkreisläufen.

Die Ingenieure unserer Kunden arbeiten zusammen mit unseren Spezialisten an der Entwicklung unserer Produkte.

Unsere Lösungen entsprechen allerhöchsten Maßstäben an die Leistungsfähigkeit und Qualität.

2、 Wie sollte eine gute Lösung einer Abdichtung definiert werden?

Welche Anforderungen sind immer von größter Bedeutung?

Dichtungslösungen sollten über ihre gesamte Lebensdauer hinweg Sicherheit bieten.

Daher arbeiten unsere Spezialisten eng mit unseren Kunden zusammen, damit unsere Lösungen für die spezifische Anwendung geeignet sind und die Anforderungen des Kunden erfüllen.

Außerdem sollte sie aus der Perspektive der Gesamtbetriebskosten einen eindeutigen Vorteil bieten.

SFC KOENIG verfügt über die brancheweit größte Produktpalette und kann daher die optimale Lösung anbieten.

SFC KOENIG blickt auf mehr als 40 Jahre Erfahrung mit Dichtungslösungen zurück – bei einer Ausfallquote im tatsächlichen Betrieb von weniger als 1 pro 1 Million (1 ppm).

3、 Wie wirken sich die Abdichtungen auf das Bremsverhalten, die Öleinspeisung, die Motoren und das Getriebe aus?

In erster Linie:

Sicherheit und Reduzierung der Auswirkungen auf die Umwelt.

Außerdem sind diese Produkte wichtig für eine ordnungsgemäße Funktion des Systems.

Die Konstruktionstechniker unserer Kunden können die Bauarten der Komponenten vereinfachen und verbessern.

Sie können die Größe und das Gewicht reduzieren, während ein hohes Maß an Sicherheit gewährleistet bleibt.

4、 Wie lauten die Produktanforderungen von SFC KOENIG hinsichtlich der Bohrungstoleranzen und der Rauheit?

Unsere Kunden können unter Beibehaltung einer überragenden Dichtheit einen höheren Toleranzbereich wählen, als dies bei anderen Lösungen der Fall ist, was eine wichtige Auswirkung auf die Kosten hat.

5、 Wo liegen im Vergleich zu herkömmlichen Dichtungslösungen die Vorteile der Produkte von SFC KOENIG?

Sicherheit in Bezug auf die Abdichtung, denn dies sind kundenspezifische Lösungen; lebenslange Abdichtung, die auf die Anwendung des Kunden zugeschnitten ist; bessere Automatisierung der Dichtungsmontage, Verkleinerung der Komponenten usw.

6、 Ich habe gehört, dass SFC KOENIG außerdem einzigartige Produkte für die Common-Rail-Einspritzung führt.

Können Sie etwas zu diesen Produkten sagen?

Wir haben eine Reihe von Dichtungstechnologien für Hochdruckbereiche, die in hohem Umfang bei Kraftstoffeinspritzsystemen eingesetzt werden.

Mit einem Arbeitsdruck von mehr als 2.000 bar haben sich diese Produkte in der Branche bereits vor vielen Jahren gut etabliert.

7、 Durchflusssteuerungen sind ein weiterer Geschäftsbereich von SFC. Welche Produkte haben Sie hier im Angebot?

Wir haben eine Reihe von Mikroventilen für die Automobilindustrie eingeführt.

Unsere bekannten Lösungen für Drosseln/Düsen werden intensiv von chinesischen Ingenieuren getestet.

8、 Würde SFC mit Kunden zusammenarbeiten, um kundenspezifische Produkte zu entwickeln?

Natürlich.

Ein gewisser Anteil unserer Fertigung besteht aus kundenspezifischen Lösungen, die auf unserer bewährten Produktlinie aufbauen.

Kundenspezifische Lösungen können für unsere Kunden einen Wert darstellen.

Mit mehr als 3 Milliarden gelieferter Dichtungsprodukte für zahlreiche Anwendungsgebiete verfügen unsere Spezialisten über die nötige Erfahrung, um gemeinsam mit unseren Kunden Konstruktionen zu optimieren, die den höchsten Sicherheitsstandards entsprechen.

9、Die Vierte Industrielle Revolution ist bereits in Sicht, insbesondere in der Automobilindustrie. Wie sehen die langfristigen Pläne von SFC KOENIG aus?

SFC KOENIG wird weiterhin für seine Kunden in der Automobilindustrie da sein, und das mit unerreichter Qualität und Zuverlässigkeit der Produkte, Lösungen, Dienstleistungen und Innovationen.

10、 Welche großen Namen befinden sich unter den Kunden von SFC?

Praktisch alle bekannten Originalersatzteilhersteller sowie Unternehmen der Ebenen Tier 1 und Tier 2.

Thu, 04/05/2018 – 16:36

SFC KOENIG is pleased to announce the appointment of Deniz Bütüner as President and General Manager of the company’s North and South American branch.

Ms. Bütüner brings to the position more than twenty years of experience at industrial companies, with a specialized expertise in shaping growth, go-to-market strategies, business development, and new product development. In her most recent position at SFC KOENIG, as the General Manager of Distribution Businesses and Strategic Marketing, Ms. Bütüner oversaw distribution sales channels, new business development, and product management for operations in the United States, Japan, China, India, Europe and beyond.

“I’m excited at the opportunity to lead the division that is responsible for the United States, Canada, Mexico, Central and South America, and to help shape the growth of the SFC KOENIG brand,” noted Bütüner. “In addition to recent production expansions at our North Haven facility, we are expanding our capabilities and customer base, and I look forward to meeting many of our customers personally as we introduce new initiatives.”

Ms. Bütüner earned a bachelor’s degree in business administration and later earned her Global Executive MBA from TRIUM, an alliance of New York University’s Stern School of Business, The London School of Economics and Political Science and HEC School of Management in Paris. Ms. Bütüner speaks five languages, including English, French, and Spanish, and has successfully led multi-cultural teams across continents for a variety of large-scale projects.

Previously, Ms. Bütüner worked out of the company’s headquarters in Zurich, Switzerland, but has recently relocated to Connecticut to take on her new role.

Fri, 11/10/2017

SFC KOENIG has increased its North American production capabilities by adding manufacturing equipment for KOENIG EXPANDER pull-style plugs in its North Haven, Connecticut facility.

“I’m excited to announce the installation of this new production machinery,” said Tom Ryan, Head of Product Management at SFC KOENIG. “Our current manufacturing operations produce the majority of push-style expander plugs shipped to North America, and this expansion allows the company to reduce lead times and meet increasing demand for a wider range of domestically-supplied components.”

The new equipment was custom built for SFC KOENIG and utilizes proven designs already in operation in the company’s Swiss production facility. North American-based production will include SK and LK series KOENIG EXPANDERS, as well as custom expander plugs developed for customer-specific requirements. The expansion of KOENIG EXPANDER manufacturing in North America will allow SFC KOENIG to respond to NAFTA-based customer orders more quickly as well as strengthen the company’s position in the market.

SFC KOENIG has increased its North American production capabilities by adding manufacturing equipment for KOENIG EXPANDER pull-style plugs in its North Haven, Connecticut facility.

“I’m excited to announce the installation of this new production machinery,” said Tom Ryan, Head of Product Management at SFC KOENIG. “Our current manufacturing operations produce the majority of push-style expander plugs shipped to North America, and this expansion allows the company to reduce lead times and meet increasing demand for a wider range of domestically-supplied components.”

The new equipment was custom built for SFC KOENIG and utilizes proven designs already in operation in the company’s Swiss production facility. North American-based production will include SK and LK series KOENIG EXPANDERS, as well as custom expander plugs developed for customer-specific requirements. The expansion of KOENIG EXPANDER manufacturing in North America will allow SFC KOENIG to respond to NAFTA-based customer orders more quickly as well as strengthen the company’s position in the market.