archive.php

分类: 行业新闻

Quality and Service Focused Throughout the COVID-19 Pandemic

Mon, 07/27/2020

A Quality-Focused Commitment to Serving Customers’ Sealing & Flow Control Needs

Throughout the COVID-19 pandemic, SFC KOENIG® has worked to protect health and safety, adapting processes to best serve customers while providing solutions for new medical applications.

As a global organization with manufacturing locations in Switzerland, Germany, the United States and China, SFC KOENIG has actively supported customers as the effects of COVID-19 spread across the globe.

“All of our manufacturing locations remain open,” stated Tom Ryan, Head of Product Management at SFC KOENIG. “We are so proud of the dedication shown by our team, who quickly adapted to these unprecedented times and continually maintained our complete commitment to quality and excellence.”

The company has modified some of its processes during recent months to help protect the health and safety of employees and visitors, as well as to provide support to customers who have new, remote working situations.

While customers are able to visit SFC KOENIG facilities, and company staff continue to be able to visit customer locations when necessary, the organization has increased its usage of video conferencing for product development support, application reviews, testing and more.

“We’re adapting and remaining flexible,” noted Ryan. “From using shared, interactive 3D CAD models that show our KOENIG EXPANDER® seals in new designs, to presenting testing results for flow control products via video conference, we have been pleased at the customer response. In everything we do we work to serve our customers with superior quality. Usually that is driven by the unsurpassed value of our product line, but now, we are adding to our value even more by working to support people in new ways that are best for their requirements and their preferences.”

As a unit of IDEX corporation, the company has benefitted from guidance on how to maintain operations, adjust process and remain compliant to standards as the pandemic evolved.

Like many modern and technology-driven manufacturers, SFC KOENIG also quickly reacted to the needs of a changing market in recent months.

“While we serve a wide variety of applications, automotive and fluid power is historically a significant portion of our business,” noted Ryan. “However, with COVID-19, there has been an increased demand for medical equipment solutions. It is part of our company’s core value system to prioritize health and safety, and we are always guided by a commitment to act as a responsible global organization. Our team has worked tirelessly to rapidly serve customers with medical application requirements, and I am proud to say that our products were used in critical applications around the world.”

With more than 5 billion parts installed and failure rates less than 1 PPM, SFC KOENIG components are recognized for unsurpassed reliability. This level of quality was an ideal fit for new medical designs and applications, in which performance was critical and operating conditions were often unique.

The company provides expander seals, check valves and flow restrictors for a wide variety of medical assemblies and devices including ventilators, respiratory devices, stretchers, hospital beds and more.

“Quality is at the core of everything we do at SFC KOENIG,” stated Ryan. “It’s in our products, the way we care for others, and how we do our jobs. Customers can continue to rely on our team and our parts for unrivaled excellence, and we look forward to working together to solve every new challenge.”

Wed, 03/18/2020

Changing requirements and on-going advancements in seals, check valves and flow restrictors.

Engine design is in the midst of a revolution. Battery-powered electric motors are replacing internal combustion engines, and support systems are adapting to new requirements. As 2020 marks the 50th anniversary of the KOENIG EXPANDER®, and the invention of the one-piece expansion seal design by the company, SFC KOENIG® is celebrating how engine and automotive design has progressed over the past five decades, and its role in innovations.

“Compared to 50 years ago, design and performance requirements are much more precise,” noted David Ramirez, Application Engineer at SFC KOENIG. “We are proud to have been involved in many significant advancements while maintaining the safety, reliability and engineering ingenuity customers expect from our products.”

In the past five decades, the number of systems viewed as “critical” has expanded. Braking applications and powertrains were often a focus. In contrast, modern designs and electric vehicles (EVs) have strict requirements for sealing and flow control products, which now serve critical roles in motor cases, transmissions, cooling systems and vehicle suspensions.

Installation reliability has always been a requirement. In the 1970’s production lines involved a number of manual operations. A seal or flow control product had to be correctly installed to prevent failure. With SFC KOENIG’s one-piece design, parts have always been easy to install, providing repeatable quality and dependable seating.

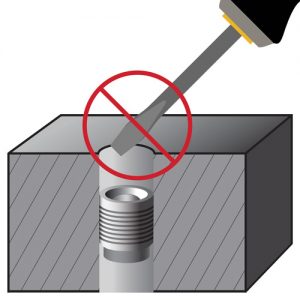

“Our expansion design securely installs and requires no chemicals or sealants,” stated Ramirez. “Components feature a serrated expansion sleeve that expands evenly into bore walls, permanently setting into the base material. There is minimal risk for the contamination and leakage common with commodity-type seals, like cup plugs and threaded screws, which are often-misaligned.”

To meet the needs of today’s operations, SFC KOENIG has adapted its part designs to easily integrate into high-speed and automated assembly lines. Without affecting reliability or effectiveness, parts have been modified making them easier to grab and position in robotic environments.

Parts also require no additional machining processes – such as threading, milling or honing – which not only eliminates manufacturing steps, but also keeps production lines free of debris.

Requirements on part positioning, performance and control have also increased for seals, flow restrictors and check valves since 1970.

“During installation, our parts are distance and force-controlled, have flexible tolerance allowances, and exert even pressures,” stated Ramirez. “That, combined with unrivaled part performance, provides precise flow control and a wide range of sealing capabilities for even highly-unique needs.”

While the company originally developed parts using various steels, lightweighting initiatives require new materials. The design of SFC KOENIG components effectively supports many composites as well as systems produced with additive manufacturing. In addition, aluminum components are now available, and the company is continually developing solutions for new materials, thin walls and complex geometries.

In the past, safety was commonly viewed by the performance of critical systems. SFC KOENIG has one of the industry’s best performance records, with field failure rates less than 1 PPM and over 5 billion parts installed.

As today’s EVs have a number of high-voltage and sensitive assemblies, seals now play a new safety role, preventing access to housings and fluid systems. SFC KOENIG components are tamper-proof and limit access by untrained users without significant, and visible damage, protecting people and preventing false warranty claims.

“At every stage of the industry and in so many innovations, SFC KOENIG parts are there,” noted Ramirez, “and we are actively working with some of the world’s largest manufacturers on cutting-edge designs. While our products and applications have advanced during the last 50 years, we remain committed to supporting customers with unrivaled performance, safety and reliability. We are excited for the future, and to be part of it.”

SFC KOENIG® is celebrating the 50th anniversary of the KOENIG EXPANDER®, and is the original inventor of the one-piece, expansion seal design.

Thu, 01/16/2020

SFC KOENIG®, a Unit of IDEX Corporation, and a leading global supplier of sealing and flow control components, is pleased to announce that its Chinese branch has moved into a new facility. The larger location allows for increased integration with IDEX China while also providing an expanded manufacturing space to support growth.

One of four main global facilities, SFC KOENIG Asia provides engineering, customer service and manufacturing capabilities and offers the company’s line of KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® flow orifices and KOENIG CHECK VALVE® components.

“The expansion of our Chinese location reflects our growing position in Chinese, Japanese and Korean automotive and fluid power markets,” noted Tom Ryan, Head of Product Management at SFC KOENIG. “While the integration of this branch into an IDEX facility will allow for a number of operational benefits, the larger manufacturing space and state-of-the-art infrastructure will help increase capabilities and output.”

The new facility is located in Xiangcheng District, Suzhou, in Jiangsu Province. The campus also houses a number of IDEX Corporation business units, allowing for streamlined support of legal, compliance, human resources and IT functions.

SFC KOENIG®, a Unit of IDEX Corporation, and a leading global supplier of sealing and flow control components, is pleased to announce that its Chinese branch has moved into a new facility. The larger location allows for increased integration with IDEX China while also providing an expanded manufacturing space to support growth.

One of four main global facilities, SFC KOENIG Asia provides engineering, customer service and manufacturing capabilities and offers the company’s line of KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® flow orifices and KOENIG CHECK VALVE® components.

“The expansion of our Chinese location reflects our growing position in Chinese, Japanese and Korean automotive and fluid power markets,” noted Tom Ryan, Head of Product Management at SFC KOENIG. “While the integration of this branch into an IDEX facility will allow for a number of operational benefits, the larger manufacturing space and state-of-the-art infrastructure will help increase capabilities and output.”

The new facility is located in Xiangcheng District, Suzhou, in Jiangsu Province. The campus also houses a number of IDEX Corporation business units, allowing for streamlined support of legal, compliance, human resources and IT functions.

星期一, 02/17/2014 – 01:00

2012年10月KVT-Koenig将紧固件事业部出售,并于2014年4月更名为 SFC KOENIG。

公司名字和标志发生了改变,但是孔瑞格仍旧专注于满足密封和流体控制领域的最高质量要求。 SFC KOENIG 的知名产品 KOENIG EXPANDER 和 KOENIG RESTRICTOR,让凯威帝成为 密封和流体控制领域的领导者。

SFC KOENIG 继承了KVT-Koenig的85年工程经验:

2012年10月KVT-Koenig将紧固件事业部出售,并于2014年4月更名为 SFC KOENIG。

公司名字和标志发生了改变,但是孔瑞格仍旧专注于满足密封和流体控制领域的最高质量要求。 SFC KOENIG 的知名产品 KOENIG EXPANDER 和 KOENIG RESTRICTOR,让凯威帝成为 密封和流体控制领域的领导者。

SFC KOENIG 继承了KVT-Koenig的85年工程经验:

- 一体化金属咬合发明者 40多年的产品经验

- 拥有IATF16949, ISO 9001 and ISO 14001 Certified

- 全球50亿次产品安装使用

- 不良率0.5 PPM之下

星期四, 09/17/2015 – 10:46

提到汽车安全,人们谈论的往往是被动安全、主动安全、信息安全,而往往忽略了汽车零部件本身的安全性。

汽车的动力总成、底盘、燃油系统、制动系统中存在着大量的工艺孔,它们原本是为了实现工艺加工的需求而

存在的,在总成装配完毕后,需要将这些工艺孔进行可靠密封,否则就会造成车辆密封性不佳的问题,从而引

起众多安全隐患。不合理的密封技术将严重影响汽车部件的总体性能。近日,盖世汽车网记者对瑞士孔瑞格集

团CEO Alparslan Kütükcüoglu先生以及孔瑞格中国公司总经理朱新宇进行了采访,就汽车工艺孔密封和流体

控制对于汽车零部件安全性和可靠性的意义进行了探讨。

从液压行业起步转型至工艺孔密封以及流体控制

孔瑞格集团(原瑞士KVT集团)目前的产品主要专注于汽车流体系统的密封和控制。公司最早从液压行业开始

,到汽车行业的动力系统、传动系统、冷却系统等都有着广泛的应用。“全世界的工程师把我们的产品和技术

,通过孔瑞格SFC KOENIG的专家支持设计到它们的高品质产品中。”Alparslan Kütükcüoglu表示。

此外,公司的原名是KVT,于2014年正式更改为了SFC KOENIG,“这代表着我们的业务发生了改变” Alparslan

Kütükcüoglu透露。盖世汽车网记者获悉,KVT是一个德文词组的缩写,“K”代表“Koenig”,是公司创

始人的姓,KVT的意思是“Koenig先生的紧固件技术公司”。近年来公司进行了产品的升级,将公司精力集中在

核心主营业务上,同时将非核心主业的紧固件业务进行了出售,以更好地专注在公司核心领域——工艺孔密封

以及流体控制。鉴于这样的战略调整和长期发展需求,公司正式更名为“SFC”,它是“Sealing and Flow Control”

的缩写,意思是“密封和流体控制”。

差异化的专业密封解决方案

盖世汽车网记者了解到,目前在欧洲工艺孔封堵方式以孔瑞格的Expander系列产品为主流解决方案。国内整

车及零部件厂商采用的工艺孔封堵方式基本还是螺纹堵、钢球封堵、碗形塞封堵。

螺纹堵的缺点在于需要工艺孔攻螺纹,浪费人工;需控制安装扭矩,一致性差;安装过程产生碎屑,影响管道

清洁;需要涂胶,费料费工。钢球封堵则需要苛刻公差和粗糙要求;密封带非常窄,易导致工艺孔微观开裂;

对钢球和工艺孔加工质量要求高,否则安装后一致性差。碗形塞封堵方法中,碗形塞靠拉伸成形,变形量和精

度难以控制;碗形塞表面的非均匀变形与孔粗糙面容易产生泄漏;需要辅助密封胶和工艺。

基于以上这些方案的短版,孔瑞格拥有拉胀堵头、球胀堵头、压胀堵头等产品。朱新宇介绍:“孔瑞格的密封

产品对孔的公差、精度要求比较低、一般情况下钻孔后可以直接装配,而且孔瑞格公司通常在客户产品设计初

期就介入,可以帮助客户减少孔的设计及加工工艺难度;孔瑞格产品的密封原理是通过产品的径向膨胀、实现

机械咬合,失效率低于1ppm,且无需铰孔、攻螺纹、涂胶、垫密封圈等任何辅助工艺;另外装配可实现半自

动、全自动,保证了产品性能的一致性。朱新宇特别强调,孔瑞格密封产品可适用于薄孔壁中、不易导致工艺

孔变形,所以工艺孔壁厚和孔深的尺寸都可以减少,能帮助客户实现产品结构紧凑化、轻量化、降成本的需求

。”

此外,孔瑞格还拥有超高压密封堵头系列来满足超高压的应用环境。Alparslan Kütükcüoglu表示:“该系列产

品可用于高压共轨系统以及高压燃油泵。这个类型的产品在市场中已经投放了很多年,经过了市场的认证。”

据悉,超高压密封堵头系列可承受工作压力超过了2000巴,并且可提供非常可靠的密封和安全性。

Alparslan Kütükcüoglu强调,流体控制是孔瑞格今后的发力重点,目前公司主要有膨胀式插装限流器、膨胀式

插装单向阀两款产品。流体控制产品同样是基于径向膨胀、机械咬合密封的原理,所以同样具有孔瑞格密封产

品与传统封堵产品相比所具有的一些优势。

发力中国市场

作为有着40多年密封解决方案的供应商,孔瑞格本着客户导向的工程开发理念,在工艺孔密封及流体控制领

域成为全球汽车行业重要的合作伙伴。Alparslan Kütükcüoglu介绍,孔瑞格工艺孔密封及流体控制产品在欧

美、日本等国家的汽车行业认可度和接受度非常高,宝马、奔驰、大众、奥迪、通用、丰田、斯堪尼亚、曼恩

等整车厂以及博世、大陆、采埃孚、博格华纳、威伯科、马瑞利、天合、德尔福、电装等核心零部件供应商均

采用了其产品和解决方案。自2011年进入中国市场以来,孔瑞格已与长城、长安、上汽、吉利、中国重汽、

一汽锡柴、潍柴、华菱汽车、泛亚等整车企业及技术研发机构进行了合作,部分产品已经施行量产。

其还透露,公司今年将在中国设立一个独资子公司,并建立本地的组装厂,同时会建立本地的测试中心,令公

司能够以最快的方式来给本地客户提供最便捷和迅速的服务,包括技术支持、产品服务和物流服务等。

(文章来源:盖世汽车网)

提到汽车安全,人们谈论的往往是被动安全、主动安全、信息安全,而往往忽略了汽车零部件本身的安全性。

汽车的动力总成、底盘、燃油系统、制动系统中存在着大量的工艺孔,它们原本是为了实现工艺加工的需求而

存在的,在总成装配完毕后,需要将这些工艺孔进行可靠密封,否则就会造成车辆密封性不佳的问题,从而引

起众多安全隐患。不合理的密封技术将严重影响汽车部件的总体性能。近日,盖世汽车网记者对瑞士孔瑞格集

团CEO Alparslan Kütükcüoglu先生以及孔瑞格中国公司总经理朱新宇进行了采访,就汽车工艺孔密封和流体

控制对于汽车零部件安全性和可靠性的意义进行了探讨。

从液压行业起步转型至工艺孔密封以及流体控制

孔瑞格集团(原瑞士KVT集团)目前的产品主要专注于汽车流体系统的密封和控制。公司最早从液压行业开始

,到汽车行业的动力系统、传动系统、冷却系统等都有着广泛的应用。“全世界的工程师把我们的产品和技术

,通过孔瑞格SFC KOENIG的专家支持设计到它们的高品质产品中。”Alparslan Kütükcüoglu表示。

此外,公司的原名是KVT,于2014年正式更改为了SFC KOENIG,“这代表着我们的业务发生了改变” Alparslan

Kütükcüoglu透露。盖世汽车网记者获悉,KVT是一个德文词组的缩写,“K”代表“Koenig”,是公司创

始人的姓,KVT的意思是“Koenig先生的紧固件技术公司”。近年来公司进行了产品的升级,将公司精力集中在

核心主营业务上,同时将非核心主业的紧固件业务进行了出售,以更好地专注在公司核心领域——工艺孔密封

以及流体控制。鉴于这样的战略调整和长期发展需求,公司正式更名为“SFC”,它是“Sealing and Flow Control”

的缩写,意思是“密封和流体控制”。

差异化的专业密封解决方案

盖世汽车网记者了解到,目前在欧洲工艺孔封堵方式以孔瑞格的Expander系列产品为主流解决方案。国内整

车及零部件厂商采用的工艺孔封堵方式基本还是螺纹堵、钢球封堵、碗形塞封堵。

螺纹堵的缺点在于需要工艺孔攻螺纹,浪费人工;需控制安装扭矩,一致性差;安装过程产生碎屑,影响管道

清洁;需要涂胶,费料费工。钢球封堵则需要苛刻公差和粗糙要求;密封带非常窄,易导致工艺孔微观开裂;

对钢球和工艺孔加工质量要求高,否则安装后一致性差。碗形塞封堵方法中,碗形塞靠拉伸成形,变形量和精

度难以控制;碗形塞表面的非均匀变形与孔粗糙面容易产生泄漏;需要辅助密封胶和工艺。

基于以上这些方案的短版,孔瑞格拥有拉胀堵头、球胀堵头、压胀堵头等产品。朱新宇介绍:“孔瑞格的密封

产品对孔的公差、精度要求比较低、一般情况下钻孔后可以直接装配,而且孔瑞格公司通常在客户产品设计初

期就介入,可以帮助客户减少孔的设计及加工工艺难度;孔瑞格产品的密封原理是通过产品的径向膨胀、实现

机械咬合,失效率低于1ppm,且无需铰孔、攻螺纹、涂胶、垫密封圈等任何辅助工艺;另外装配可实现半自

动、全自动,保证了产品性能的一致性。朱新宇特别强调,孔瑞格密封产品可适用于薄孔壁中、不易导致工艺

孔变形,所以工艺孔壁厚和孔深的尺寸都可以减少,能帮助客户实现产品结构紧凑化、轻量化、降成本的需求

。”

此外,孔瑞格还拥有超高压密封堵头系列来满足超高压的应用环境。Alparslan Kütükcüoglu表示:“该系列产

品可用于高压共轨系统以及高压燃油泵。这个类型的产品在市场中已经投放了很多年,经过了市场的认证。”

据悉,超高压密封堵头系列可承受工作压力超过了2000巴,并且可提供非常可靠的密封和安全性。

Alparslan Kütükcüoglu强调,流体控制是孔瑞格今后的发力重点,目前公司主要有膨胀式插装限流器、膨胀式

插装单向阀两款产品。流体控制产品同样是基于径向膨胀、机械咬合密封的原理,所以同样具有孔瑞格密封产

品与传统封堵产品相比所具有的一些优势。

发力中国市场

作为有着40多年密封解决方案的供应商,孔瑞格本着客户导向的工程开发理念,在工艺孔密封及流体控制领

域成为全球汽车行业重要的合作伙伴。Alparslan Kütükcüoglu介绍,孔瑞格工艺孔密封及流体控制产品在欧

美、日本等国家的汽车行业认可度和接受度非常高,宝马、奔驰、大众、奥迪、通用、丰田、斯堪尼亚、曼恩

等整车厂以及博世、大陆、采埃孚、博格华纳、威伯科、马瑞利、天合、德尔福、电装等核心零部件供应商均

采用了其产品和解决方案。自2011年进入中国市场以来,孔瑞格已与长城、长安、上汽、吉利、中国重汽、

一汽锡柴、潍柴、华菱汽车、泛亚等整车企业及技术研发机构进行了合作,部分产品已经施行量产。

其还透露,公司今年将在中国设立一个独资子公司,并建立本地的组装厂,同时会建立本地的测试中心,令公

司能够以最快的方式来给本地客户提供最便捷和迅速的服务,包括技术支持、产品服务和物流服务等。

(文章来源:盖世汽车网)

星期五, 11/10/2017 – 10:37

SFC KOENIG has increased its North American production capabilities by adding manufacturing equipment for KOENIG EXPANDER pull-style plugs in its North Haven, Connecticut facility.

“I’m excited to announce the installation of this new production machinery,” said Tom Ryan, Head of Product Management at SFC KOENIG. “Our current manufacturing operations produce the majority of push-style expander plugs shipped to North America, and this expansion allows the company to reduce lead times and meet increasing demand for a wider range of domestically-supplied components.”

The new equipment was custom built for SFC KOENIG and utilizes proven designs already in operation in the company’s Swiss production facility. North American-based production will include SK and LK series KOENIG EXPANDERS, as well as custom expander plugs developed for customer-specific requirements. The expansion of KOENIG EXPANDER manufacturing in North America will allow SFC KOENIG to respond to NAFTA-based customer orders more quickly as well as strengthen the company’s position in the market.

SFC KOENIG has increased its North American production capabilities by adding manufacturing equipment for KOENIG EXPANDER pull-style plugs in its North Haven, Connecticut facility.

“I’m excited to announce the installation of this new production machinery,” said Tom Ryan, Head of Product Management at SFC KOENIG. “Our current manufacturing operations produce the majority of push-style expander plugs shipped to North America, and this expansion allows the company to reduce lead times and meet increasing demand for a wider range of domestically-supplied components.”

The new equipment was custom built for SFC KOENIG and utilizes proven designs already in operation in the company’s Swiss production facility. North American-based production will include SK and LK series KOENIG EXPANDERS, as well as custom expander plugs developed for customer-specific requirements. The expansion of KOENIG EXPANDER manufacturing in North America will allow SFC KOENIG to respond to NAFTA-based customer orders more quickly as well as strengthen the company’s position in the market.

星期四, 04/05/2018 – 16:36

SFC KOENIG is pleased to announce the appointment of Deniz Bütüner as President and General Manager of the company’s North and South American branch.

Ms. Bütüner brings to the position more than twenty years of experience at industrial companies, with a specialized expertise in shaping growth, go-to-market strategies, business development, and new product development. In her most recent position at SFC KOENIG, as the General Manager of Distribution Businesses and Strategic Marketing, Ms. Bütüner oversaw distribution sales channels, new business development, and product management for operations in the United States, Japan, China, India, Europe and beyond.

“I’m excited at the opportunity to lead the division that is responsible for the United States, Canada, Mexico, Central and South America, and to help shape the growth of the SFC KOENIG brand,” noted Bütüner. “In addition to recent production expansions at our North Haven facility, we are expanding our capabilities and customer base, and I look forward to meeting many of our customers personally as we introduce new initiatives.”

Ms. Bütüner earned a bachelor’s degree in business administration and later earned her Global Executive MBA from TRIUM, an alliance of New York University’s Stern School of Business, The London School of Economics and Political Science and HEC School of Management in Paris. Ms. Bütüner speaks five languages, including English, French, and Spanish, and has successfully led multi-cultural teams across continents for a variety of large-scale projects.

Previously, Ms. Bütüner worked out of the company’s headquarters in Zurich, Switzerland, but has recently relocated to Connecticut to take on her new role.