TECHNICAL INFORMATION - Check Valve Design Guidelines

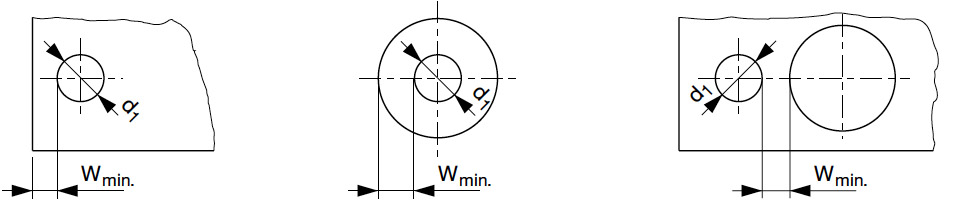

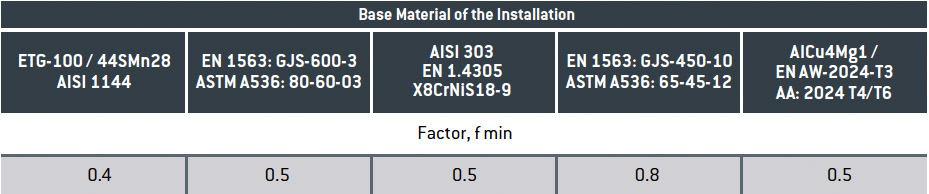

Wall Thickness / Distance From Edge

As the radial expansion of the KOENIG CHECK VALVE® sleeve occurs, the base material in which it anchors plastically deforms. The resultant strength, as well as the hydraulic pressure and temperature service conditions depending on the characteristics of the base material, require a minimum wall thickness or distance from edge.

The guideline values for minimum wall thickness and distance from edge (Wmin.) express these influencing factors. At these minimum values, only slight deformation on the exterior profile of the base material of less than 20 μm is likely. This does not affect the function of the KOENIG CHECK VALVE®. Below the guideline values (Wmin.) the possibility of overloading the base material exists, which can adversely influence the function of the KOENIG CHECK VALVE®. In such cases, tests must be conducted.

Wmin. = fmin. x d1

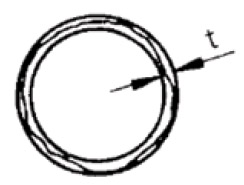

Roundness Tolerance

To ensure reliable functioning of the KOENIG CHECK VALVE® with regard to pressure performance and to ensure leak tight sealing, a roundness tolerance of t = 0.05 mm must be held. By using a double-lipped twist drill, the called out hole and roundness tolerances are reached. Better tolerances, particularly for larger diameter holes, can be held by using a triple-lipped twist drill.

Conicity of the Bore

Within the effective anchorage area of the KOENIG CHECK VALVE®, the bore must be in accordance with the dimensional sheets. The bore lead in can be chamfered up to a depth of 0.25 x d1 (check valve diameter) because this area has no significant effect on the anchorage function.