Automotive Check Valve Pressure Relief

Automotive Check Valve Pressure Relief

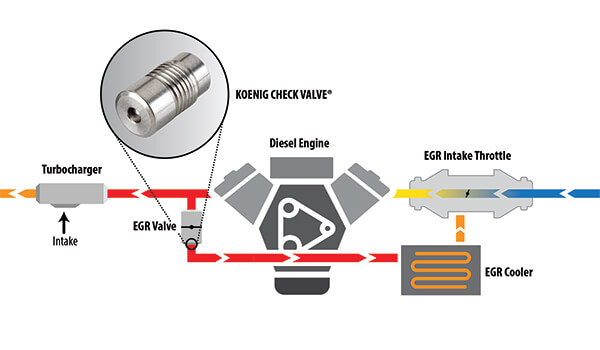

As automotive manufacturers work to achieve efficiency goals, legacy assemblies are increasingly being analyzed to identify new opportunities to save space, reduce weight and modernize designs. Recently, SFC KOENIG® worked with a commercial vehicle tier supplier in the redevelopment of an exhaust gas recirculation (EGR) system. Through the integration of a KOENIG CHECK VALVE® pressure relief solution, the customer was able to create a more compact assembly that met strict performance and reliability requirements.

The automotive check valve over pressure component provided critical safety functions that maintained exhaust system performance even during high-pressure conditions.

From early in the design phase, the SFC KOENIG engineering team collaborated with the customer to review installation challenges, including small bore sizes, complex port configurations and difficult installation locations. A special KOENIG CHECK VALVE® 5.5mm reverse flow pressure relief design was selected for the application and configured to meet specific application requirements.

During normal exhaust system operation, the automotive check valve remained closed. However, when system pressures increased – typically due to higher temperatures – and reached the pre-determined 10bar cracking pressure, the valve would open, channeling exhaust gasses back into the fuel system. When pressures lowered to 8bar, the valve would automatically close.

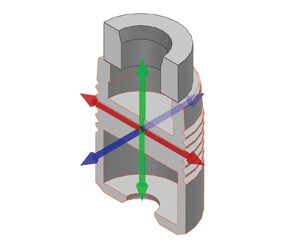

The new fuel system design featured thin port walls. The design of KOENIG CHECK VALVE®components is based on an expansion principle, effectively addressing thin-wall challenges by evenly distributing stress in the housing, both during installation and throughout long-lifecycle operations.

During assembly of the EGR valve, installation equipment efficiently positions the one-piece BR 5.5 valve into the proper location within the port. The part’s serrated external sleeve is then expanded into the port walls, creating a secure metal-to-metal seal which permanently sets the pressure relief valve in place. With controlled, even, low radial forces and no torsional forces throughout the entire installation process, the SFC KOENIG solution minimizes port deformation, cracking and damage to the base material.

Additionally, SFC KOENIG components support flexible alignment tolerances, and are designed to achieve precise positioning in deep hole installations. This allowed the automaker to position the automotive check valve within the assembly, ensuring a safe, strong and reliable installation within the complex system geometries.

Installation of the KOENIG CHECK VALVE®relies only on metal-to-metal interface, requiring no chemical sealants or additional machining processes, reducing the risk of contamination.

SFC KOENIG engineersworked with the customer to identify the correct installation location as well as force and distance controls. During development, the team also provided analysis testing, reporting and reviews, collaborating with the customer throughout the redesign process. SFC KOENIG’s extensive experience partnering with some of the world’s largest automakers, combined with the proven track record of KOENIG solutions – with failure rates less than 1 PPM and more than 5 billion parts installed – allowed the customer to focus on large system integration challenges, while the SFC KOENIG team could focus on the exhaust gas recirculation pressure relief automotive check valve function.

Learn more about our full line of engineered sealing and flow control solutions, including KOENIG EXPANDER® plugs, KOENIG RESTRICTOR® components and KOENIG CHECK VALVE® flow control solutions, or contact us today.

single.php