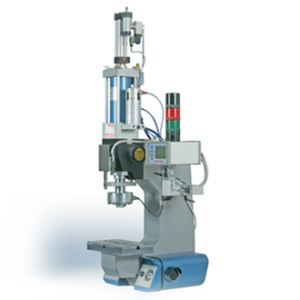

SETTING TOOLS EXPRESS 3000/5000 – OVERVIEW

Hydropneumatic setting tool for the installation of KOENIG EXPANDER®. Quick tool change avoids long changeover times. The required working stroke is preprogrammed and can be retrieved by the Expander type to be processed (max. 64 memory locations). In addition, the working stroke is referenced for each individual Expander, which guarantees high process stability and quality. The press is force and distance controlled; an RS232 or USB interface can be used to trace corresponding data on the customer’s computer for later processing. The required software is included in the scope of delivery.

EXPRESS 3000 –

For the installation of KOENIG EXPANDER Series MB, and CV from Ø 3 – 10mm (.156″ – .375″inch), KOENIG CHECK VALVE BF and BR 5.5 and 8mm, and KOENIG RESTRICTOR Series RE from Ø 4 – 10mm.

EXPRESS 5000 –

For the installation of KOENIG EXPANDER Series MB and CV Ø 12 – 22mm (.406″ – .437″ inch).

| SETTING TOOL DATA | |||||||||

| Express 3000 | Express 5000 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height | approx. 1360 mm | Height | approx. 1470 mm | ||||||

| Width | approx. 340 mm (max. 530 mm) | Width | approx. 400 mm (max. 580 mm) | ||||||

| Depth | approx. 495 mm | Depth | approx. 535 mm | ||||||

| Table (width x depth) | 220 x 160 mm | Table (width x depth) | 300 x 190 mm | ||||||

| Weight | approx. 140 kg | Weight | approx. 190 kg | ||||||

| Compressive Force | 30 kN (max. force 29.5 kN at 6 bar) | Compressive Force | 50 kN (max. force 52.5 kN at 6 bar) | ||||||

| Working Stroke | 10 mm (within the cylinder ram) | Working Stroke | 15 mm (within the cylinder ram) | ||||||

| Working Speed | 40 mm/sec (max. possible at 6 bar) | Working Speed | 30 mm/sec (max. possible at 6 bar) | ||||||

| SETTING TOOL DATA | |||||||||

| Express 3000 and Express 5000 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Working area (height) | 250 mm (working height between table top and cylinder, without setting tool) | ||||||||

| Working area (depth) | 200 mm (center-line spacing between cylinder and C frame) | ||||||||

| Cylinder ram | 60 mm | ||||||||

| Operating voltage | 230 V/110V, automatic switchover to corresponding power supply | ||||||||

| Operation | VISUAL POINT terminal with QVGA graphic display | ||||||||

| Force/distance control | Sensor adjusted with SIT reference sensor | ||||||||

| Software | WINSCOPE Software for connecting to a PC | ||||||||