50 Years of Sealing & Flow Control

Wed, 03/18/2020

Changing requirements and on-going advancements in seals, check valves and flow restrictors.

Engine design is in the midst of a revolution. Battery-powered electric motors are replacing internal combustion engines, and support systems are adapting to new requirements. As 2020 marks the 50th anniversary of the KOENIG EXPANDER®, and the invention of the one-piece expansion seal design by the company, SFC KOENIG® is celebrating how engine and automotive design has progressed over the past five decades, and its role in innovations.

“Compared to 50 years ago, design and performance requirements are much more precise,” noted David Ramirez, Application Engineer at SFC KOENIG. “We are proud to have been involved in many significant advancements while maintaining the safety, reliability and engineering ingenuity customers expect from our products.”

In the past five decades, the number of systems viewed as “critical” has expanded. Braking applications and powertrains were often a focus. In contrast, modern designs and electric vehicles (EVs) have strict requirements for sealing and flow control products, which now serve critical roles in motor cases, transmissions, cooling systems and vehicle suspensions.

Installation reliability has always been a requirement. In the 1970’s production lines involved a number of manual operations. A seal or flow control product had to be correctly installed to prevent failure. With SFC KOENIG’s one-piece design, parts have always been easy to install, providing repeatable quality and dependable seating.

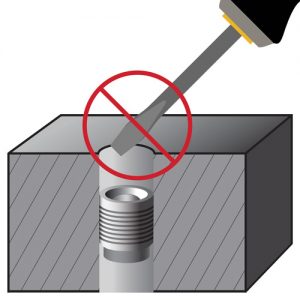

“Our expansion design securely installs and requires no chemicals or sealants,” stated Ramirez. “Components feature a serrated expansion sleeve that expands evenly into bore walls, permanently setting into the base material. There is minimal risk for the contamination and leakage common with commodity-type seals, like cup plugs and threaded screws, which are often-misaligned.”

To meet the needs of today’s operations, SFC KOENIG has adapted its part designs to easily integrate into high-speed and automated assembly lines. Without affecting reliability or effectiveness, parts have been modified making them easier to grab and position in robotic environments.

Parts also require no additional machining processes – such as threading, milling or honing – which not only eliminates manufacturing steps, but also keeps production lines free of debris.

Requirements on part positioning, performance and control have also increased for seals, flow restrictors and check valves since 1970.

“During installation, our parts are distance and force-controlled, have flexible tolerance allowances, and exert even pressures,” stated Ramirez. “That, combined with unrivaled part performance, provides precise flow control and a wide range of sealing capabilities for even highly-unique needs.”

While the company originally developed parts using various steels, lightweighting initiatives require new materials. The design of SFC KOENIG components effectively supports many composites as well as systems produced with additive manufacturing. In addition, aluminum components are now available, and the company is continually developing solutions for new materials, thin walls and complex geometries.

In the past, safety was commonly viewed by the performance of critical systems. SFC KOENIG has one of the industry’s best performance records, with field failure rates less than 1 PPM and over 5 billion parts installed.

As today’s EVs have a number of high-voltage and sensitive assemblies, seals now play a new safety role, preventing access to housings and fluid systems. SFC KOENIG components are tamper-proof and limit access by untrained users without significant, and visible damage, protecting people and preventing false warranty claims.

“At every stage of the industry and in so many innovations, SFC KOENIG parts are there,” noted Ramirez, “and we are actively working with some of the world’s largest manufacturers on cutting-edge designs. While our products and applications have advanced during the last 50 years, we remain committed to supporting customers with unrivaled performance, safety and reliability. We are excited for the future, and to be part of it.”

SFC KOENIG® is celebrating the 50th anniversary of the KOENIG EXPANDER®, and is the original inventor of the one-piece, expansion seal design.

single.php