AUTOMOTIVE TRANSMISSION SEALING PLUG

PROPER SEAL SELECTION ELIMINATES AIR SPACE IN AUTOMATIC TRANSMISSION

As 8, 9 and even 10-speed automatic transmissions become more common, system complexity and sensitivity has increased. With additional speeds comes the requirement for additional clutch actuation ports to be added to the transmission shaft, resulting in less space between ports and thinner port walls. While delivering increased fuel economy and better performance, these modern transmission systems have much less operational tolerance.

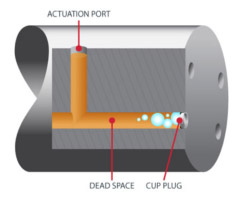

When a major automotive manufacturer noted noise and rough shifting in their new multi-speed automatic transmission systems, engineers began a system-wide analysis. They eventually focused on dead space within the cross-drilled channels that connected the clutch actuation ports. These channels allowed for even distribution of transmission fluid, but created approximately 6-inches of space between an actuation port and the transmission shaft seal. The dead space became an area where air would collect, which was determined to be a major source of the performance issues.

The manufacturer brought the project to SFC KOENIG® for evaluation. SFC KOENIG engineers reviewed the cross-drilled channel design, and noted that the manufacturer had continued to use the same cup plug seals that had been used in their older, less advanced transmissions.

The cup plugs, which sealed holes at the surface of the transmission shaft, resulted in the dead space that allowed air pockets to form. While these air pockets were not problematic in the operation of their older designs, the new transmission systems were much more sensitive.

“While often selected for their low price, cup plugs present a number of challenges, especially in precision and deep bore applications,” said Nate Moore, Product Manager at SFC KOENIG. “In this project we knew that sealing at the surface was not a good solution, and cup plugs couldn’t be installed deep within a drilled shaft, deep in the transmission. Ensuring proper installation of a cup plug in that type of location would be extremely difficult. In this design there would be no way to visually inspect the seal integrity or to access an improperly installed seal for a repair. A failed seal would result in complete transmission failure.”

Cup plug installation offers little tolerance for variation. The installation system must provide accurate alignment, apply even and controlled pressure, and deliver a precise stroke to create a secure seal. The aspect ratio of cup plugs, which tend to be large in diameter but “short” in height, make alignment more difficult. Additionally, pressure points created by installation tools make the cup plugs susceptible to deformation and can lead to a reduction in seal effectiveness. There is also an inherent risk of contamination from sealant, which most cup plugs require to maintain seal integrity.

Other common sealing solutions, such as threaded pipe plugs, were also not viable options. Even if the threaded plug was long enough to fill the dead space, the forces applied to the port walls during installation would be high and would likely damage the shaft. Other sealing solutions required additional machining processes, such as drilling and tapping, which would increase costs, production effort, and the risk of contamination from metal debris.

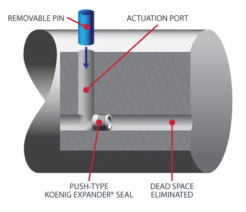

Working with the customer, SFC KOENIG suggested a solution that could be reliably positioned deep within the bore. A push-type KOENIG EXPANDER® MB 850 Series would be installed at the edge of the clutch actuation port, eliminating the space that allowed air pockets to form.

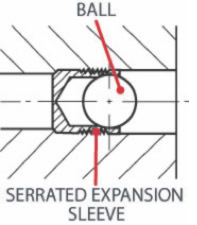

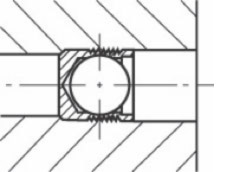

KOENIG EXPANDER plugs featured a unique serrated sleeve and ball. During installation, the ball would be forced into the sleeve, causing the plug to expand into the base material. This would create a permanent metal-to-metal seal that would not require sealant, and could be installed in the existing gun-drilled port without additional machining operations.

“Our KOENIG EXPANDER® plugs were the type of engineered sealing solution a high-performance application like this requires,” continued Moore. “Our components are proven. We have installed more than 3 billion components with field failure rates less than 1 PPM (part per million). We were confident the component could be installed deep within the transmission block without concern. After testing and evaluation our customer was also able to realize the value in our one-piece, engineered expander seal.”

SFC KOENIG worked directly with the manufacturer, not only providing the sealing technology, but also to develop a solution to integrate their products in the manufacturer’s production environment.

While high-speed installation tools were accurate, there was concern for variation caused by positioning tolerances in the automated environment. SFC KOENIG engineers developed an additional positioning method to ensure optimal placement was achieved.

During installation, a temporary, removable pin was inserted into the actuation port. The KOENIG EXPANDER was inserted into the deep gun-drilled channel, pushed until it came into contact with the pin, and then expanded. After the seal was installed, the pin was removed. This ensured that the plug was not inserted too deep in the channel, which could block part of the actuation port, and also provided maximum contact between the plug sleeve and the port walls. The seal ensured the most direct fluid path and blocked access to the “dead space” behind the expander.

With the new KOENIG EXPANDER plugs in place, problems associated with air pockets were eliminated. Testing of the new transmission was successful and the SFC KOENIG solution was utilized in large-scale production of the transmission systems.

Given the performance and reliability of the KOENIG EXPANDER in this application, engineers have begun to work with SFC KOENIG to evaluate other opportunities where this expander seal technology can be applied, such as hydraulic manifolds, pumps, cylinder heads and engine blocks.

single.php